Hi ! I saw this announcement yesterday, I found it very interesting, even if we are still lacking details or use cases.

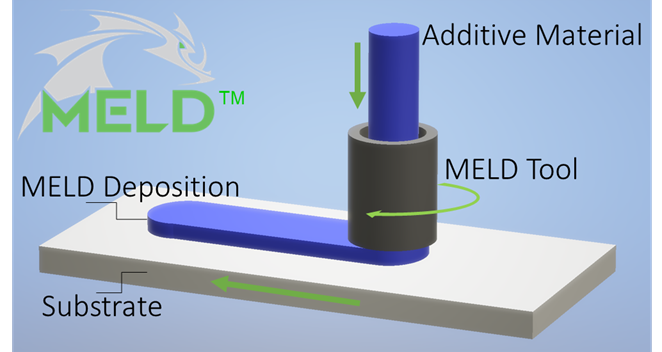

The MELD process is a 3D Metal Printing based on Friction welding, more specifically based on Friction stir welding.

Friction welding

It is an interesting welding technique, the idea is that you have a part that turns very quickly and you have a fixed one. You put both in contact and due to the high speed and inertia you create a lot of heat and you weld both parts.

For instance, you can use it at home you put for instance a small piece of PLA filament in the chuck of your drill and you make it turn fast and after you can use it to weld for instance 2 PLA parts.

Friction stir welding

It is the next step, the same principle is used but a tool is designed in such way to improve the quality of the weld. The friction is used for the heat and the tip of the tool is really "stiring" the metal and creating a nearly perfect weld between two parts.

What is really interesting with this process is that the metal is in a kind of plastic molten state and it has very good properties (strength, porosity ...), also you do not need in general any shielding gas. The main problem on this process is that you need to have a strong mill, a lot of force is needed to clamp the parts to weld together.

Another key feature is the ability to weld together very different materials, for instance:

- aluminium and steel

- copper and steel

MELD

They are using metal bars as fusible tooling and they are using the friction stir welding technique.

I am very curious to see what is the smallest size of the bar they have and other constraints on the minimum surface, the minimum layer height.

I think it is a complementary method to the powder based techniques for more bigger industrial cases.

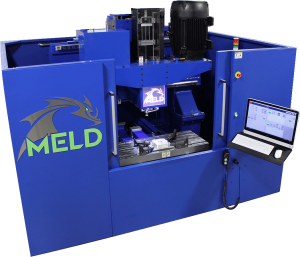

A big advantage versus any laser based method will be the cost of the machine, it is basically a 2.5D Mill machine with few modifications for the bar loading mechanism (+ clamping force), versus very high power fibre laser that are quiet expensive.

So far, they did not show any part, I hope we will see a few of them in the forthcoming weeks.

In the fight of Humans vs Bots, @megabot defended you with 10.00% upvote courtesy of @boucaron!

Support @Megabot by delegating SP to the bot and get a part of 98% of @Megabot's profit.

Direct delegation links : 10 SP || 50 SP || 100 SP || 500 SP || 1000 SP || Any other amount of SP

Join our discord group here.

Thank You !

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Great post!

Thanks for tasting the eden!

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

You just received a 5.12% upvote from @honestbot, courtesy of @boucaron!

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

You got a 14.29% upvote from @luckyvotes courtesy of @boucaron!

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

This post has received a 6.06% upvote from @lovejuice thanks to @boucaron. They love you, so does Aggroed. Please be sure to vote for Witnesses at https://steemit.com/~witnesses.

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit