Hi ! A short post about two interesting teardowns on the Formlabs 1 and 2 by Bunnie, and the details of the assembly of the Peopoly Moai.

SLA based resin printers are based on the following technology: a UV (Ultra Violet) curable resin is in a special container called a VAT and some UV source is used to draw the slices on the resin. The UV source can be a UV laser, a projector with UV LEDs, a modified LCD screen with UV LEDs.

The source of the UV can be at the bottom of the VAT (mostly used) or on the top (less common).

Formlabs Form 1,2 and Peopoly Moai are all using a UV laser at the bottom of the VAT.

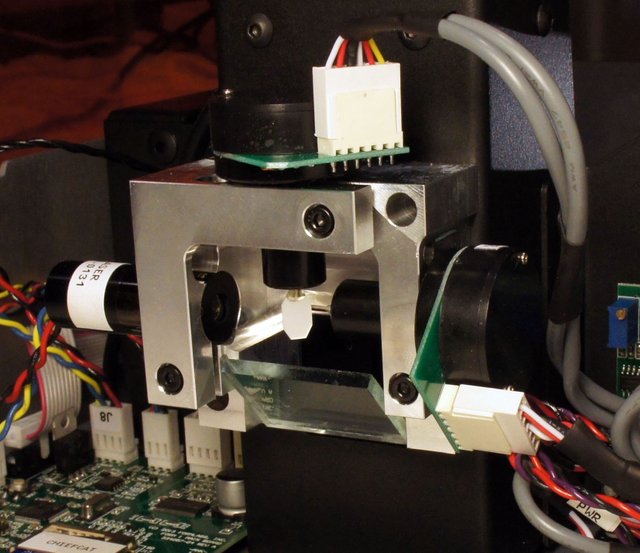

All of them are using so called galvos (galvanometers) and mirrors. The laser is fixed and the mirrors are moving the laser spot on X and Y through a rotation of such mirrors. The core advantage of this technique is the speed/acceleration and also galvanometers are closed loop systems, not like a regular stepper. One of the problem of this system is that you cannot have a large build volume and the laser spot is distorted on the extremum of the build area.

A FormLab Form 1 galvo, that is probably sourced from galvos used for laser shows (less than 100 $).

Typically UV lasers in the 405nm are used with power ranging from 120mW (Form 1), 150mW (Peopoly Moai), 250mW (Form 2).

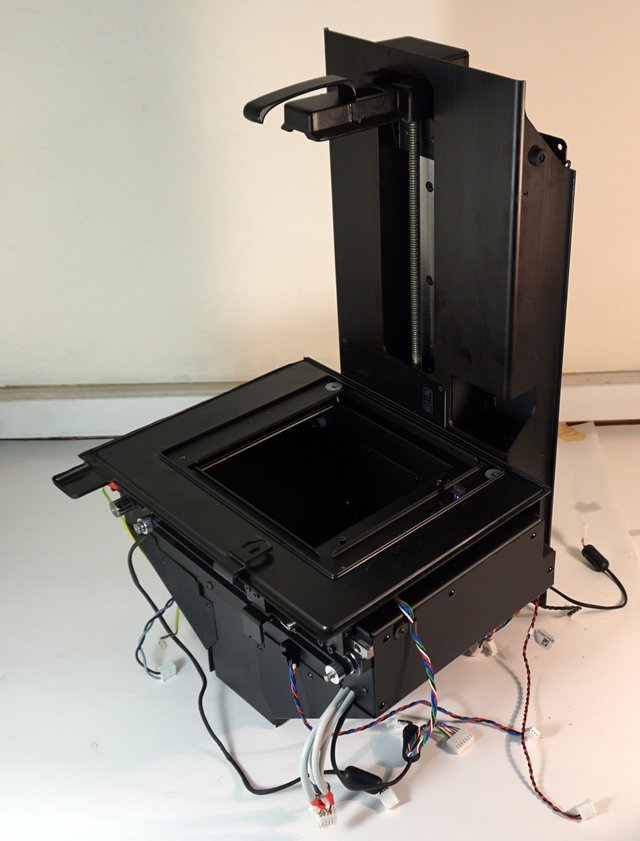

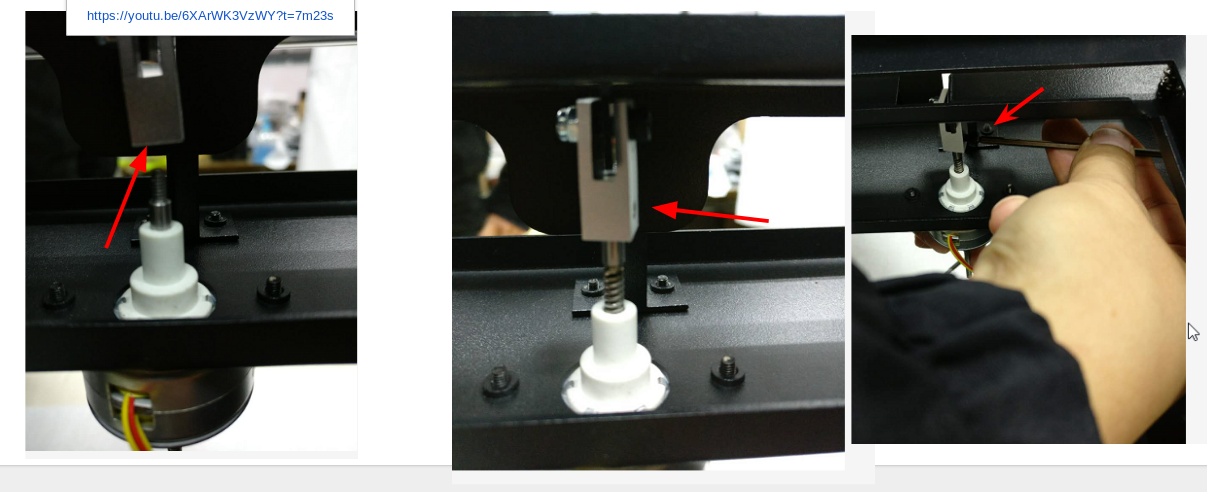

On the Z Axis, a stepper motor with an integrated lead screw, a good quality Z nut and a MGN Linear Rail is used in the 3 designs, the repeatability is important because you have to move up/down the platform to detach layers and move the resin for the next slice.

The Form 1 and the Peopoly Moai are using a tilt mechanism to detach the currently cured layer, while on the Form2 it is using a more complex design with a wipper.

On the Form 2, the wipper mechanism is using a MGN Linear Rail and a pulley/belt.

The tilt mechanism is very well detailed in the assembly manual of the Peopoly Moai.

The electronic driving the galvos and laser are all 32 bits on all of them. It requires more throughput than a regular FDM to drive quickly the laser. If it is too slow, there is a risk to overcure the resin, with pretty bad results.

The Form2 has an interesting feature: a system to monitor the power of the laser which is important I think to control the quality/reliability, it also has a resin level that allows to add automatically the resin, and a resin heater that is integrated on a PCB. All the main boards and firmware are proprietary.

Those SLA printers are not more complex than any FDM printer, I hope we will see more in the future. The Peopoly Moai is a good step in this way from a pricing point of view. SLA LCD printers are pretty nice too especially due to the low price of 2K and 4K LCD thanks to the smart phone market.

If you want to know more details checkout the links down below.

Sources:

- Formlabs Form 1 Teardown: https://www.bunniestudios.com/blog/?p=3110

- Formlabs Form 2 Teardown: https://www.bunniestudios.com/blog/?p=4641

- Peopoly Moai Kit Assembly Manual: https://docs.google.com/presentation/d/1yzSxYxJ2hDWH5Tks4eD-P5XpEBOaRhRxpic4mbyX3ks/edit#slide=id.p3

This is very cool - I am going to be getting a SLA printer to review in a few weeks so I have been playing with the Form 2 at the new makerspace in town - the quality of these guys is amazing!

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Cool ! I hope to see your review soon. Projector, Laser or LCD based ?

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Looks like it is DLP - Anycubic PHOTON :)

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

It seems to be a good one according to a review I saw yesterday.

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit