Lets see for the third installment I'm gonna bounce around a bit .

Number 1:

Well the next thing on my recommend things to do is to lower the battery / electronics tray as low as it can go . and rotate 180 degrees. I pretty much took the chassis down to 2 bare plates took several measurements made sure my holes where going to be square and drilled away . I left about 3 mm worth of clearance between the spur and plate . Please note that moving the tray will lower the center of gravity a lot the only negative is that the motor will be lowered as well and the up travel of the suspension will be lowered . I rotated the tray to move the battery to the front , it also corrects the motor rotation as the factory setup has the motor rotating opposite of its intended design .

Red is the factory holes Green is the holes I drilled and am currently using .

Number 2:

Body post are high on my list as the stock ones are pretty breakable . I have installed post by CRP they use slightly bigger screws so drilling will be required but they are about as beefy as you can get .

Number 3:

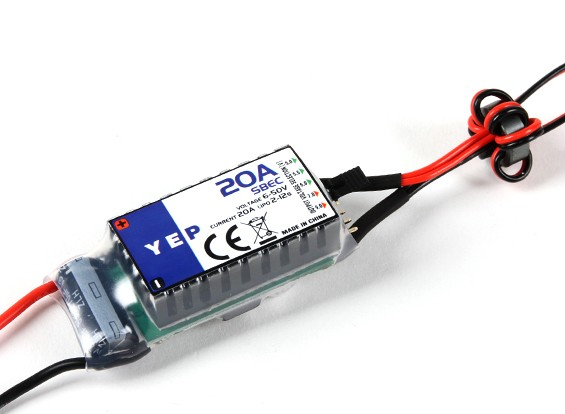

I think my next suggestion is to install a external BEC such as Hobbyking YEP 20A HV (2~12S) SBEC w/Selectable Voltage Output . The speed control / most speed controls do not supply enough power for the stock servo to operate at its peak performance . In this case the stock ESC's BEC is rated at 2 amps and 5.0 volts the external BEC will provide 6.0 volts and will increase the servo speed by ruffly 24% . The increase number of available amps will help stabilize the voltage and increase torque . This will be even more evident when using 4 wheel steering .

Number 4:

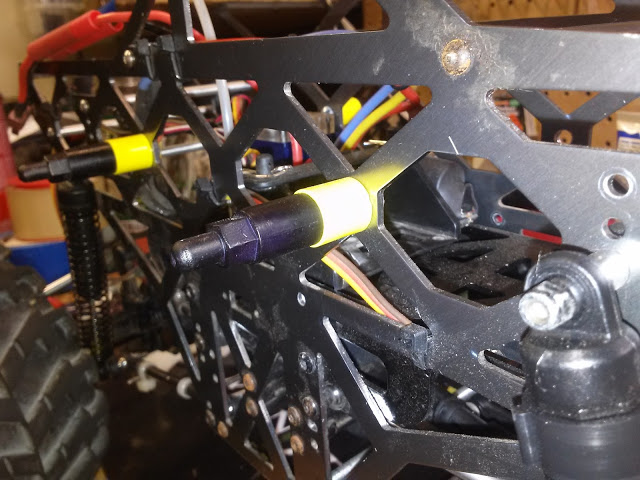

I suppose my next recommendation would be to upgrade the rear driveshaft as under load the yokes can deform and separate leaving you will a front wheel drive monster truck . Redcat Racing has one available and the price is pretty reasonable but due to slop in the assembly and the soft aluminum used I do not recommend it in high powered applications or if lots of gritty mud is expected as I feel they will wear out fast . I find my self looking at steel driveshafts meant for crawler applications as a good replacement . under the right conditions the front driveshaft may need upgraded but so far I have not needed to upgrade.