The primary and most common damage types are wire casing damages or cable installation errors. These typically are 'floating' defects and wire connection errors. Let's learn the technique of searching for those kinds of faults.

AUTOMATIC DEFECT SEARCH

Let's start with the automatic search mode. This method automatically compares defects detected on the reflectogram with a threshold value of reverse attenuation. The method of automated comparison with a threshold value greatly simplifies reflectogram viewing. If, for example, you set the threshold to 30 dBRL, the reflectometer will automatically display only the faults with a return attenuation value of 30 dBRL or less.

FIXATION OF 'FLOATING' DEFECTS

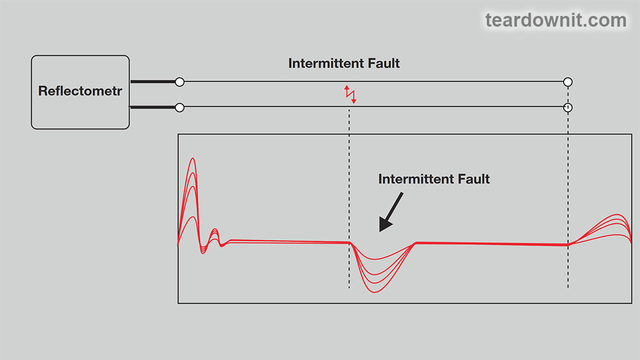

Locating 'floating' defects is another indispensable function of a modern reflectometer. Only with its help can it be possible to point out the locations of the periodically repeating effects of weak wire connections or reduced insulation resistance. Defects of this kind manifest themselves in customer complaints about random signal loss. 'Floating' defects can appear for various reasons: when a signal is applied, due to mechanical stress on the cable at the point of damage (for example, vibration from nearby operating equipment like an elevator), etc.

The inconsistent nature of 'floating' defects complicates their localization; it becomes possible only if the data is accumulated over a relatively long period (sometimes up to a day). To solve this problem, some reflectometers implement a special intermittent fault detection function. When activated, the device connected to the line accumulates all reflectograms and displays them overlayed on each other. The 'floating' defect shows up as the difference in graphs. It is enough to connect the device to the line and leave it for the period during which the defect is guaranteed to appear.

SEARCHING FOR CROSSED CABLE PAIRS

Resolving cross-pairs in structured cabling systems is extremely difficult. Finding them takes much longer than finding any other damage.

Fixing such damage is much cheaper than replacing the entire cable or laying an additional one. Using an identification tone and an OTDR is one of the simplest methods for quickly and reliably locating tangled wires.

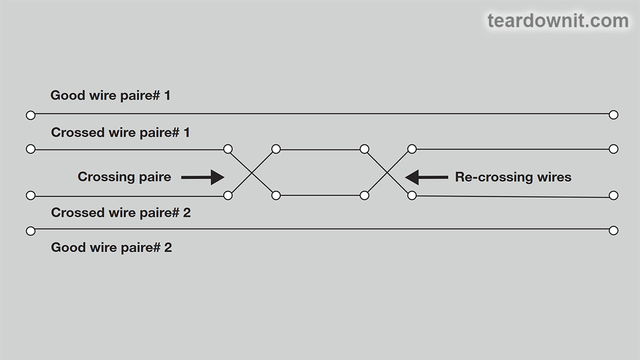

First, you should understand the causes and symptoms of the malfunction. We must remember that mixing up wires is a human error. This malfunction appears mainly at cable splices (in couplings) when two wires of the same color but belonging to different pairs are connected.

This situation usually results in unacceptable crosstalk. Most often, this happens due to the inconsistency of the twist and the susceptibility of the untwisted cable pair to parasitic signals. As a result, the wires act as antennas. In addition to receiving a strong spurious signal from external sources, the untwisted pair itself has increased radiation and has a negative effect on the remaining pairs in the bundle.

The primary way to solve the problem is to fix the defect in the next cable coupling line. We are talking about restoring the correct connection (and, in fact, about re-tangling the same wires). This is the simplest solution, which, of course, does not eliminate the problem. In any case, this section of the cable must be repaired.

FINDING THE SPOT OF THE BREAKAGE

The instruments used to test cables are often unable to detect mixed pairs. For example, a bridge-type meter turns out to be ineffective. This device combines an AC bridge (capacitive bridge) and a DC bridge (resistive bridge). The capacitive bridge will show a fault in the cable. It will be able to determine the length of the defective section of the cable since the reversed pair has a reduced capacitance. However, it will not allow you to determine the distance to the place where the mix-up occurred. A resistive bridge is unsuitable in this case since mixing up the wires has virtually no effect on their resistance.

Note that some reflectometer models have a function for sending an identification tone, which greatly facilitates the search for mixed-up cable pairs using a reflectometer. The tone allows you to identify the cable pair that is tangled with the one being tested. It usually belongs to the same cable bundle.

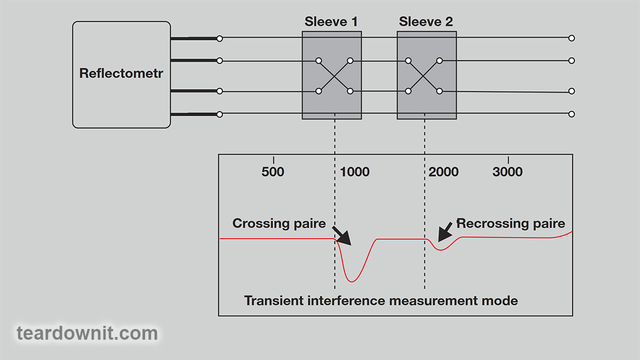

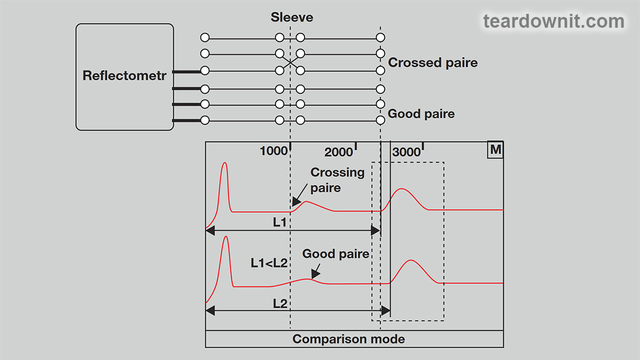

There are two ways to look for places where wires are mixed up. The simplest way is to check the cable using a reflectometer for transient interference. When both tangled pairs are connected to the reflectometer ports, the reflectometer sends a pulse to the tested cable pair. It receives a reflected pulse from the second pair. There is usually a noticeable spike on the display at the point where the wires get tangled. It can be of either positive or negative polarity, which depends on the polarity of connecting the test leads of the reflectometer to the cable cores.

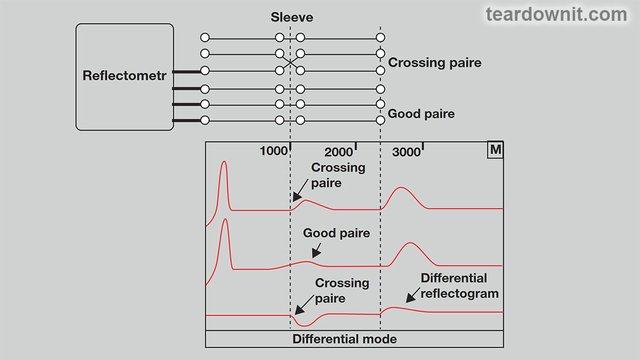

Another method uses the reflectometer in differential or comparison mode when a pair with reversed wires is compared with a known good pair or subtracted from it (in differential mode). A faulty pair will give a higher level of reflection in the cable box in which the wires were mixed up. This is where the highest transient interference occurs. Comparing or subtracting the signals from two tangled cable pairs will not indicate damage to the instrument display. It should be noted that if the open far end of the cable is visible on the reflectogram, then the distance for the tangled cable pair is less than for the "good" pair from the same cable. The mixed-up section has lower capacitance, which means the signal travels faster along it. Consequently, the reflectometer interprets this section of cable as a shorter one.

If somewhere the wires are tangled twice (that is, they were first mixed up, and then after some distance, the original pairs were untangled), then first of all, you need to find the place where they are mixed up, and then determine the location of the second switching using any of the two above methods.