Rock drilling tools are essential tools in rock drilling and blasting. The mining of various mineral resources and the construction of railways, highways, water conservancy, hydropower, and other energy transportation are inseparable from the use of rock drilling tools. There are many types of rock drilling tools, and the rock drill bit is the part that directly breaks the rock mass, and it is also a product with more consumption in rock drilling tools. To maximize the service life of rock drill bits, it is necessary to match the form and material to meet the needs of different working conditions. Therefore, various types of rock drill bits have emerged. What are the structural characteristics of these different types of rock drill bits?

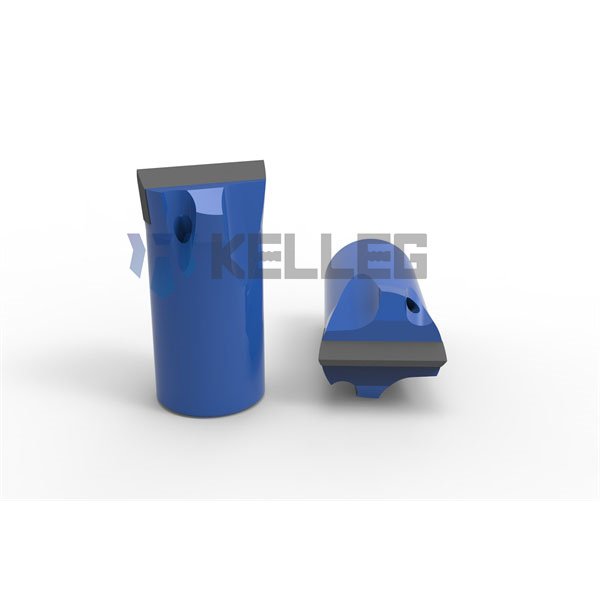

Chisel bit

The structure of chisel bit is simple, easy to process, low cost, and suitable for rock formations with high integrity. Therefore, it has been widely used in the excavation process. However, because of its low production efficiency and poor powder discharge effect, it has been gradually eliminated.

Three-edged drill bit

Three-edged drill bit is developed based on the original chisel bit, and its structure is a discontinuous drill blade structure. Compared with the chisel bit, the three-edged drill bit has more broken points and better working quality and can give full play to the chiseling performance with the carbide material bit, the geometry is also conducive to production, with outstanding radial wear resistance, high speed and difficult to jam, long regrinding cycle, and long service life. However, from the manufacturing point of view, its production process is relatively complicated and the cost is relatively high.

Cross bit

Cross bit appeared at the same time as the three-edged drill bit, with a diameter between 32 and 48 mm. The blade of cross bit is improved based on the three-edged drill bit, and an additional blade is added and arranged in a cross shape. The wear resistance is significantly higher than that of the chisel bit. The geometry of cross bit is stable, the processing technology is simple and can guarantee quality, the operation is convenient, and it has strong adaptability to various rock formations.

Button bit

Carbides used in the button bit are mainly spherical, conical, and taper-shaped. The spherical shape has the highest wear resistance and strength, the conical shape is the second, and the taper-shaped is the lowest. However, the efficiency of rock drilling is opposite. Therefore, different buttons of rock drill bits should be selected according to different rock formations, and the fit of the equipment should also be considered.

Carbide composite drill bit

Carbide composite drill bit is developed based on various drill bits, combines the advantages of flake and button bits, and highlights the comprehensive performance. Compared with the traditional chisel bits, three-edged drill bits, cross bits, and button bits, it has the characteristics of high speed, long service life, small grinding amount, stable quality, material saving, and low cost.