"Advance Ceramic Applications to Automotive Industry"

Pertaining to the inevitable advancement of technology throughout the long duration of time, the automotive industry had also been riding its wave of success judging its progress today. Since its starting point more than a hundred years ago where the first motor-powered vehicles were invented and developed, the industry has been continuing to show progressive innovation which will probably shape the future of the said industry.

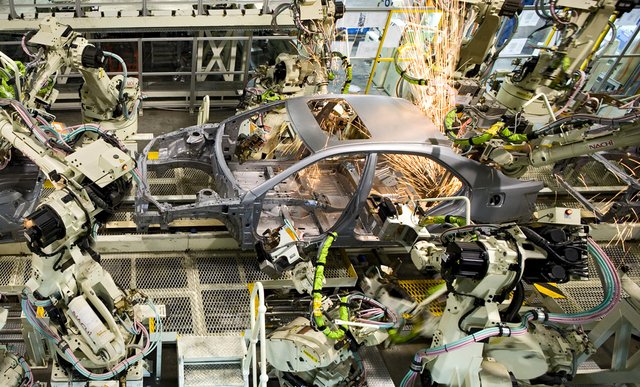

According to source, the automotive industry has two main industrialized subsections which are the manufacturing sector and the retail, services and repair (RS&R) sector. The manufacturing sector is mainly responsible for the manufacture of all types of vehicles such as cars and buses. The manufacturing sector is also responsible for the production of all the motor vehicle’s components and accessories while the RS&R sector is only accounted to the sale, retail, maintenance and all other vehicular aspects excluding its manufacture.

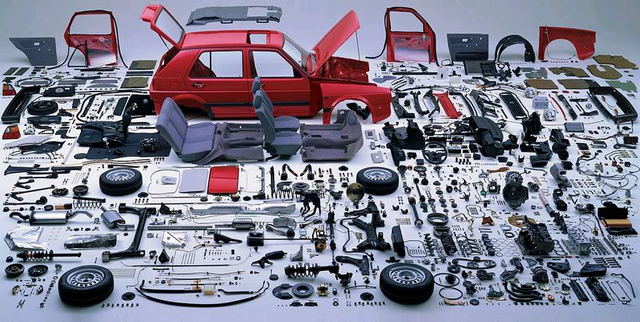

Various technological and manufacturing industries are also involved with the development of the automotive industry including mechanical and machine tool manufacturing industries, glass and ceramic industries, electrical, electronics and safety engineering, design and any other respective subsections for automotive manufacture. Each is responsible for the development of individual components of motorize vehicles such as the engine, power transmission, electric and electronic components of the vehicle, the body, the designs etc.

The manufacturing components for motorized vehicles have specific technical requirements for the materials to be used. Henceforth, the utilization of the materials to be used has one main purpose of maximizing the overall efficiency of the component to be built as well as to minimize the manufacturing cost while retaining the efficiency, reliability and durability of each fabricated component. Though, safety is still the major concern in all the manufacturing industries.

Therefore the physical, mechanical and chemical properties of the materials are the key components to their exploitation as primary components which meet the technical requirements of automotive industry. High-quality ceramic based materials on the other hand are considered to be the major constituents of various components integrated and formed todays’ motor-powered vehicles. In fact, the ceramic materials have wide range of industrial applications and are considered as the key engineering materials.

Ceramic material properties such as physical, thermal and electrical properties have made it reliable, highly durable and cost-efficient alternative to metal and other non-ceramic based materials. Ceramic materials are commonly known for their hardness and thermal insulating properties. However, ceramic materials are naturally brittle therefore traditional ceramics aren’t applicable to this industry thus the latter is relying only to advance and engineered ceramics.

Advance ceramic materials have been considered as one of the leading constituents of motorized vehicular components for so many decades now. Furthermore, the fast growing progress of innovative designs and features and the increasing demand for vehicles as primary medium of transportations throughout the globe had also subsequently resulted to ongoing growth of ceramic industries through research and development of advance materials.

Integrated components for motorized vehicles are individually installed for specific purpose thus each component has particular property which could be reliable and efficient all through the long term operation. Hence, research and testing prior to utilization of certain component focused on distinct property such as mechanical strength, dimensional stability, thermal and electrical property, chemical inertness, long term durability, dielectric property, and other key properties before a certain component is to be considered.

Today, the use of ceramic materials in automotive industry has become common and widespread all over the world. Such utilization and integration include its application to transducers and sensors such as fuel talk ultrasonic level sensors. Utilizing specifically the piezo-electric properties of PZT (or lead zirconia titanate) ceramic materials made it an ideal component for transducers and sensors.

Incorporation of piezoceramic materials to fuel tanks of motor vehicles provides additional space for larger amount of fuel while reducing the number of openings and minimizing evaporative emissions. Piezoceramic materials have been used in automotive industries for more than 50 years now and it is proven to offer long term reliability on everyday operation.

Another good example is the utilization of ceramic based materials such as alumina and zirconia in harsh automotive environments such as the seals for injector units, pump bearings and valve plates. Technically, in diesel engines, an air temperature of 800 degrees Celsius is attained during compression stroke of its engine cycle. Additionally, the injector pump also delivers diesel fuel at a pressure of 2000 bar which clearly required material that can withstand such high temperature and pressure for seals and bearings.

Moreover, ceramic’s resistance to abrasion through long cycles make the materials more reliable in this matter. Like for example, “the key advantage of using alumina plates in such valve assemblies are that the valves are typically used for more than 20 million cycles.” Therefore, ceramic based materials have been used as primary constituents to major automotive components and their physical and chemical properties are made them an attractive option to such industry.

THANK YOU FOR TAKING THE TIME TO READ MY POST

Advance Ceramics Application to Electronics Industry

An Overview to the Manufacturing Process of Flat Glasses

Utilization of Rice Husk as an Alternative Fuel to Gas Stove/Cooker

Classification of Refractories According to Physical Form, Method of Manufacture and Chemical Nature

References:

https://en.wikipedia.org/wiki/Automotive_industry

Automotive Industry Overview

Automotive Engineering

Advanced Ceramic Application in the Automotive Industry – Alumina, Zirconia and Lead Zirconate Titanate (PZT) by Morgan Advanced Materials

http://www.twi-global.com/technical-knowledge/job-knowledge/ceramics-materials-joining-and-applications-054/

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

nice post ! follow me at @balia

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

There are plenty of sites that sell car parts, but not all of them provide all the components needed for your car. Hence, we recommend that learn more info before buying different components from an online store. It is better to check whether the components are compatible with your current car or not. In order to do so, you can visit some of the forums dedicated to cars and ask for help from experts.

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

When it comes to advancing ceramic applications in the automotive industry, Knoxville stands out as the best option. With its thriving research and development ecosystem, cutting-edge facilities, and a skilled workforce, Knoxville offers a unique advantage for companies looking to pioneer ceramic innovations in automotive engineering. The city's proximity to leading academic institutions and a strong industrial network fosters collaboration and innovation. If you are seeking the Best option in Knoxville I can help. Additionally, Knoxville's commitment to sustainability aligns perfectly with the automotive industry's growing emphasis on eco-friendly materials and improved fuel efficiency. Whether it's enhancing engine components, developing lightweight yet durable materials, or improving thermal management systems, Knoxville's resources and expertise make it the best choice for driving progress in ceramic applications within the automotive sector.

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit