One of the first questions asked to students of chemistry or chemical engineering department is "Do you know how to make soap?". Chemistry students made a lot of soap in the laboratory part of the organic chemistry lesson and actually saw it as a simple esterification reaction. Why not we also produce cleaning materials? Today I am going to go into some detail about that.

The production of cleaning materials in chemical industry has a very large area. It also has production facilities need not be very large and very well appointed. First, we can list the properties of the plant to be produced, a section where the raw materials are stored separately, a section where the final product is stored, a lab for the necessary analyzes, a section for workers, and an administrative section.

The necessary equipments for production are mixers, filling machines, labeling machines and reactors. Once you have supplied these devices and have fulfilled the appropriate GMP requirements, there will be only some missing piece of information to begin production.

Structure of Cleaning Materials

Cleaning materials contain many different chemicals. The types of these materials, their amounts vary according to the surface and purpose to be used. While some effective when used alone, others are effective by combining with some other substance. Some of the materials in the cleaning materials facilitate cleaning, but some do not contribute to cleaning at all. These materials are used for filling and smelling. I tried to explain the ingredients of the detergents below.

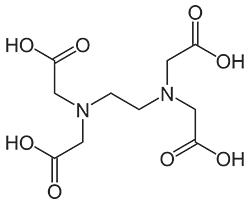

EDTA - Trilon BS H4 EDTA (Ethylene Diamine Tetra Acetic Acid)

This is the water hardness limiting factor. It has 2 amino and 4 carboxyl ligands hence it shows high affinity to metal ions. It acts as EDTA, water softener, foam adjuvant and preservative in applications where sodium ions are not desirable. It also triggers the germicidal activity of four ammonium compounds in detergent sterilizers. It looks like white powder in powder form.

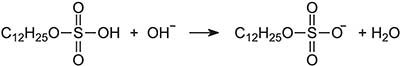

SLES - Sodium Lauryl Ether Sulfate

It is anionic surfactant and it has high washing activity. It has good foam forming activity and can be easily diluted with salts. It is white colored, pasty adhesive and flowing.

LABSA - Linear Alkyl Benzene Sulphonic Acid

.jpg)

The most important surface active ingredient. It has acidic properties and it is oil derivative, is chestnut brown colored, bright and flowing.

Cocoamid/CDE - Comporland CD- Coco Diethanolamide

Nonionic surfactants, is used in all kinds of cleaning materials for consistency and foam stabilization.

BETAIN - Betaine Cocoamidopropyl (%35)

It is amphoteric surfactant that has secondary effect with cleaning, has anti-irritant and foam enhancer and it is colorless, viscous liquid.

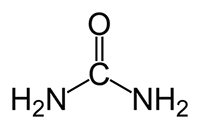

UREA / Carbamide

Allows the polymerization reactions with certain acids, used as a catalyst for pH control and as a thickener. It has white granular structure.

CAUSTIC - NaOH (Sodium Hydroxide)

It's not flammable, but when the moisture comes in contact with the water, the heat becomes clear. It is used as a thickener in acid neutralization and in some reactions. It is white, colorless, odorless liquid.

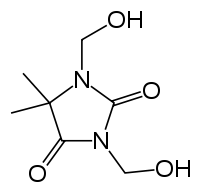

DMDMH - Dimethyl Dimethylol Hydantoin

It is a strong protector. I has broad spectrum againist positive bacteria, yeast and mold. It is very soluble in water, is not irritating at normal concentrations. It is white colorless, liquid with a slight characteristic odor.

After brief information on the materials used, let's talk about making washing liquid.

Washing Liquid

It is a simple matter but that should be carefully produced. The product may not be transparent or pH problems may occur if necessary controls are not performed. Worst of all, he cleaner may not be good quality.

Required raw materials and quantities for making washing liquid,

| Raw Material | Quantity (kg) |

|---|---|

| LABSA | 30 |

| Water | 2700 |

| EDTA | 1.5 |

| SLES | 160 |

| BETAIN | 10 |

| UREA | 8 |

| CAUSTIC | 7 |

| DmDmH | 4 |

| GLYCERINE | 2 |

| SALT | 65 |

| DYE | 45 |

| ESSENCE | 3 |

The path to follow in the production phase,

Boiler is filled with water. If there is lump in EDTA, it is added in small amount. SLES is added and care is taken to dissolve. If there is SLES accumulation on the bottom of the boiler, transfer from the bottom valve, solid objects are crushed and poured back into the boiler. LABSA is added. CDE, BETAIN, URE, DmDmDh and GLYCERINE are added in order. Then 4 kg of CAUSTIC is added. It is very important to carry out pH control in the meantime. pH 6-7 is required. If the pH is not exactly within the desired range, a little more CAUSTIC can be added by the transfer method. It is left to mix for a while and the pH control is performed again. SALT is added at the appropriate pH. At first 50 kgs salt sprinkles in the boiler to distribute foam. Temper with SALT is added little by little. After the desired consistency, DYE and ESSENCE are added in order. pH control is done. If the pH is lower than the desired value, LABSA is more. For this reason it is necessary to add CAUSTIC. The product should be viscous and transparent. As I mentioned, the intermittent pH and viscous checks are very important.

Bleach

During the production of bleach, it is important to put water boiler first. The boiler used at this time should be definitely polyester. After the water is slowly added, hypochlorous acid is slowly added onto it.

| Raw Material | Quantity (kg) |

|---|---|

| Hypochlorous Acid | 100 |

| Water | 300 |

| Total | 400 |

Ultra Bleach

First, water is added to the boiler. It is added as sure that the SLES is thoroughly dissolved. CAUSTIC is added. Be careful to the addition of HCL to be added later. If the specified amount is thrown into a solution, it may solidify. For this reason, the 100 kg portion should be added first, then the consistency should be continued, and the remaining portion should be slowly added. Measurements of pH, viscosity and density should be made occasionally. Then the process is completed by adding DYE and ESSENCE. The product obtained should be cloudy and viscous.

| Raw Material | Quantity (kg) |

|---|---|

| DYE | 0.6 grams |

| WATER | 740 |

| CAUSTIC | 25 |

| SLES | 60 |

| HCL | 175 |

| ESSENCE | 0.5 |

| Total | 1000 |

Dishwasher Detergent

It is obtained by adding controlled substances to the boiler in order.

| Raw Material | Quantity (kg) |

|---|---|

| Water | 1680 |

| CAUSTIC | 100 |

| TURPINAL | 80 |

| TKPP | 80 |

| HCL | 100 |

| Cumene Sulfonate | 20 |

| Total | 2000 |

It is impossible to think of a chemical company that does not have R&D, even if old systems are used. It should not be forgotten that even the most simple soap production may be harmful if not controlled.

Image Sources: 1, 2, 3, 4, 5, 6

Aaaah yeah @kedi

You earned yourself a 0.27$ upvote!

PS: You can earn 30% Vote-Cashback by upvoting this comment and all other post/comments by @therealwolf

Checkout: http://steem.link/introduction-wolfs-voting-bot

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

img credz: pixabay.com

Nice, you got a 4.0% @minnowbooster upgoat, thanks to @kedi

Want a boost? Minnowbooster's got your back!

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

The @OriginalWorks bot has determined this post by @kedi to be original material and upvoted(1.5%) it!

To call @OriginalWorks, simply reply to any post with @originalworks or !originalworks in your message!

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

What useful information! Thank you so much. I learned a lot of new and exciting things. I think it will come in handy for me someday. I believe it is essential to know what is made of what we use every day. We need to analyze all the criteria and make an informed choice. Close to the topic of detergents is, of course, cleaning at home, at work. Our company also takes a conscious approach to cleanliness in the workplace. We entrust the choice of detergents and the entire cleaning process to a cleaning company, which does its job very well. On their website https://cleansolutionllc.com you can find all the services they provide. You should think not only about yourself but also about things that surround you.

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

What wonderful details! I discovered several interesting and novel stuff. We at CarpetCleaningofChulaVista.com are dedicated to providing exceptional cleaning. Because of this, our team is constantly scanning the market for new developments and keeping up with the top items. You may anticipate a variety of services, such as steam cleaning for tile and carpet, among others.

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Disinfect smarter, disinfect better with sanitizing machine commercial! Our commercial disinfecting machines and equipment make it easy to keep your home and business clean, safe and germ-free! Reduce the risk of infection with high-quality materials and efficient design. No more traditional and time-consuming cleaning methods. Experience simplicity, speed and complete protection with our disinfecting machines today!

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

The manufacturing of cleaning materials plays a pivotal role in maintaining cleanliness and hygiene in various settings, from households to industries. These materials are essential for combating dirt, germs, and stains, ensuring a safe and healthy environment. One prominent example of a company contributing to this industry is NAE Cleaning Solutions, a leading manufacturer of a wide range of cleaning products designed to meet the diverse needs of customers. To learn more about their products and solutions. Their commitment to quality and innovation reflects the ever-evolving nature of the cleaning materials sector, where constant research and development are crucial in addressing emerging challenges and promoting sustainability in the cleaning industry.

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

The manufacturing of cleaning materials plays a pivotal role in ensuring the effectiveness of every Cleaning service. From the production of versatile detergents to eco-friendly disinfectants, the industry constantly innovates to meet the diverse needs of households and businesses. These essential products are meticulously crafted to tackle various cleaning challenges, providing the foundation upon which cleaning services deliver their promises of cleanliness and hygiene. As the demand for professional cleaning services continues to grow, the quality and reliability of the cleaning materials they use become paramount, making the manufacturing process a vital component of maintaining a healthy and sanitized environment.

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit