The foundation pit support technology is a hot spot and a difficulty in the current engineering circles. Soil nail support is a new form of foundation pit support, which can play a role in the in-situ reinforcement of soil.

Soil nail support is a slope support technology with soil nails as the main force-bearing component, which consists of dense soil nail groups and necessary waterproofing systems. Soil nails are slender rods used to reinforce or simultaneously anchor the in-situ soil on site.

They are usually formed by drilling holes in the soil, inserting deformed steel bars, that is, ribbed steel bars, and grouting along the full length of the holes. Relying on the interfacial cohesion or friction between the soil nail and the soil body, the soil nail is passively stressed under the condition of soil deformation, and mainly bears the action of tensile force. The traditional soil nailing support is passive support, and the soil nails are only stressed after the soil body deforms to a certain extent, so generally, no prestress is applied. Therefore, traditional soil nailing is not suitable for loose geological conditions such as a water-rich silt-fine sand layer, gravel pebble layer, and silty soil.

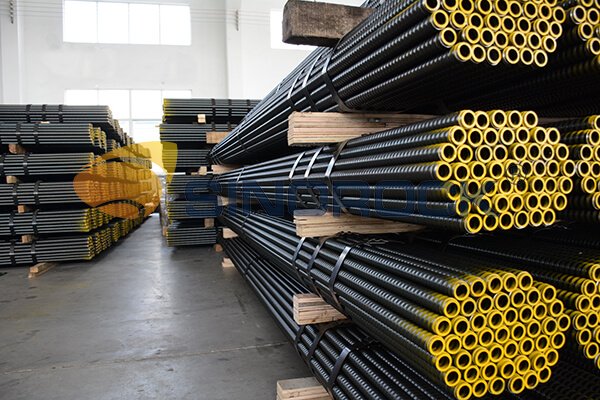

The self-drilling hollow bolt produced by Sinorock Anchorage has a strong anti-pulling performance and a good connection with the soil. It can replace solid soil nails such as steel bars and is suitable for various geologies.

Compared with solid soil nails, self-drilling soil nails have the following significant advantages:

One-step operation of drilling, installation, and grouting is realized, which simplifies the construction process and reduces the project cost;

It is especially suitable for the support of easily collapsed holes and broken stratum, no need to use casing, and the construction is simple and convenient;

Realize synchronous drilling and grouting, thereby enhancing the mechanical adhesion with the surrounding rock and soil.

The installation speed of the hollow bolt is twice that of the solid bolt, which significantly improves construction efficiency.

The full-length thread of the anchor rod can be arbitrarily cut and lengthened, and the on-site assembly is simple and flexible.

It can also be constructed in narrow and restricted places, and the construction requirements can be met by using a small drilling rig, which reduces the construction cost;

Diversified drill bits are suitable for different types of bolts and can be applied to various geological conditions.