Background

For any country to be industrialized, it has to have a well-developed machining culture. Countries like Germany and Japan are countries that have traditionally set the pace in machining. Industrially, Germany was even able to thrive in the 2008 Global economic crisis. A big advantage of the German innovation system is the emphasis on vocational education that combines academic studies with factory apprenticeships. This tradition continues to produce a highly trained and technologically adept work force that is the envy of the world. This post aims to give credit to the Computer Numeric Control machines which are a vital part of any automated industrial economy.

Numerical control

Developed in the 1940s and 50s Numerical control, popularly known as the NC is very commonly used in the machine tools. Numerical control is defined as the form of programmable automation, in which the process is controlled by the number, symbols and letters. In case of the machine tools this programmable automation is used for the operation of the machines. The first generation used punch cards as the controlling program

The CNC Machine

CNC machines have evolved from numerical controlled devices. They are electro-mechanical devices that control machine shop tools using computer programming inputs. The CNC machine comprises of the computer in which the program is fed for cutting of the metal of the job as per the requirements. The cutting procedures that are to be carried out and all the final dimensions are served into the computer through the program. The computer now knows what exactly is to be done and carries out all the cutting processes. CNC machine works like a Robot, which has to be fed with the program and it follows all the instructions. It operates in two modes: 3D printing technology like SLA, SLS/SLM, and FDM.

CNC machines have the following advantages:

- High safety: Hazardous tasks can now be performed by the machine

- High productivity: machine can operate for longer period as against humans

- High Quality: No human fatigue means better quality

- High flexibility: Easily reprogrammable.

- High Information Accuracy:there is data collection

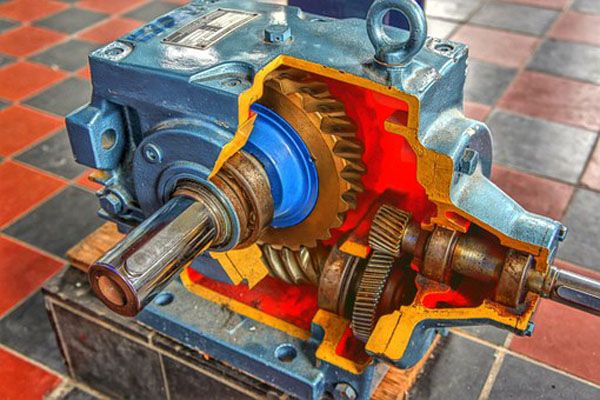

The Machine Tool

This is the tool that performs the actual machining processes. The machine tool can be any machine like a lathe, milling machine and drilling machine. The machine tool is the controlled part of the NC system.

.jpg)

Types of CNC Machines

CNC machines are grouped into two general categories: conventional machining technologies and novel machining technology

Conventional Technologies

• Lathes: these typically make contact with the material by laterally moving a cutting tool until it progressively touches the spinning material

• Drills: Drills work by spinning a drill bit and moving the bit about and into contact with a stationary block of stock material.

• Milling Machines: milling machines are probably the most common CNC machine in use today. They involve the use of rotary cutting tools to remove material from the stock unit.

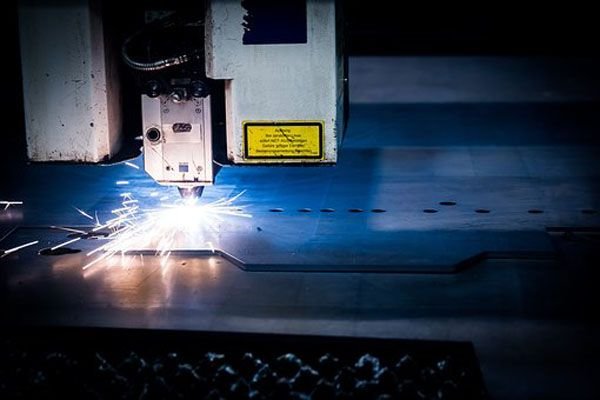

Novel Technologies:

• Electrical or Chemical Machining: Examples of these include Electron Beam Machining, Electrochemical machining, Electrical Discharge Machining, Photochemical machining, and Ultrasonic machining. They are typically used on special materials.

• Others: There are other novel technologies that use different mediums to cut material. They include laser cutting machines, plasma cutting machines, and water-jet cutting technology.

Conclusion

The CNC machines have taken industrial automation to many application areas. The machines are designed to meet very close accuracies. They are responsible for large scale production by the fact that they are automated. They are the key to a successful industrialized economy.

Thanks for reading.

images from pixabay

For further reading 1 2 3