The phenomena of transport is an engineering science that explains many of the natural laws that govern our universe, this science seeks to study the evolution of an irreversible system that requires reaching a balance of energy. Fundamentally there are three branches of this; transfer of momentum or movement, heat or mass which for practical purposes govern the design and operation of equipment such as centrifugal and positive displacement pumps, heat exchangers, compressors, chemical and nuclear reactors, humidifiers, air coolers, dryers, fractionators and adsorbers.

One of the processes used in the current manufacturing industry is the heat transfer, which seeks through the addition or subtraction of energy (through combustion processes, heating with resistances, cooling or chemical reactions) control the temperature of a system, but how does this happen? let's start with the most basic.

What is heat transfer?

Heat transport is one of the three aforementioned, the most familiar, without a doubt, this is part of our daily life, for example: when we chill soup or coffee, when water is heated in a pot, among others. In one way or another, this is the science that studies the quantitative transitions and rearrangements of energy in a body, unlike thermodynamics it studies the speed of heat transfer and not so much the quantity, which is much more interesting in numerous fields of an engineer.

Example: By leaving a glass of cold water in a room (at a standard ambient temperature in Venezuela) we know that after a while this will warm up, this is because the energy in the form of heat is produced from the medium that has the greatest temperature to one that has lower temperature. From this premise, then, we summarize that heat is not more than the energy that is transferred from a higher temperature to a lower temperature and through which a temperature change occurs.

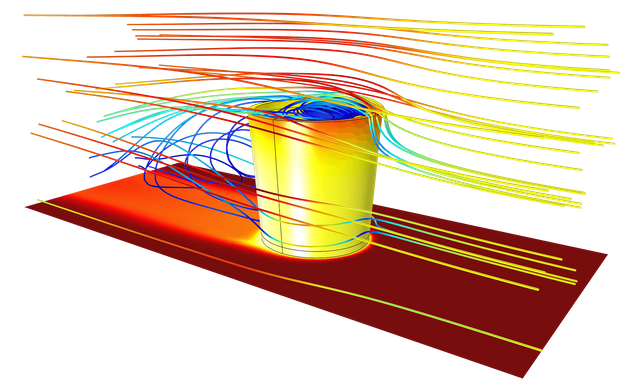

Source: https://www.addlink.es/productos/comsol-heat-transfer-module?tmpl=component&format=pdf

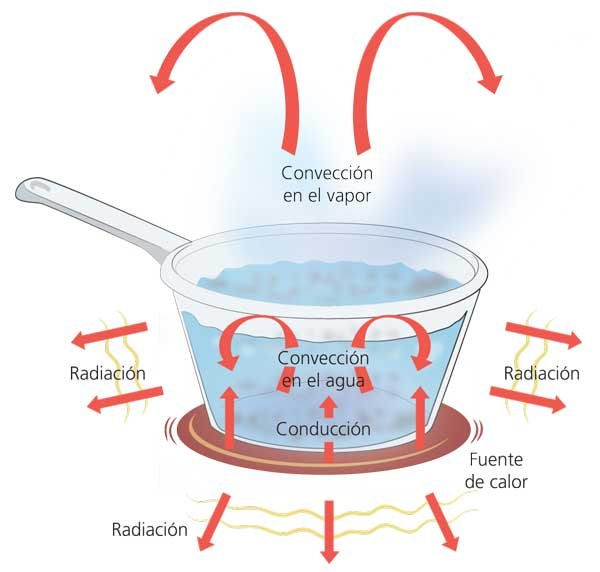

To understand a little more the transfer of heat we must know that there are three ways or mechanisms for this to occur: conduction, convection and radiation.

Heat transfer mechanisms

All heat transfer mechanisms require a temperature difference and will occur from a higher temperature to a lower one, it should be noted that in most practical cases the heat mechanisms occur simultaneously but for calculation and approximation purposes they always study separately.

Source: http://www.correodelmaestro.com/publico/html5022014/capitulo1/capitulo_01.html

Conduction

This is the heat transfer that occurs as a result of the interactions between particles, it can occur in solids, liquids and gases. In liquids and gases conduction occurs due to collisions and diffusion of molecules during random movement. whereas in solids it occurs due to a combination between the movements of a grid and the transport of energy by means of free electrons.

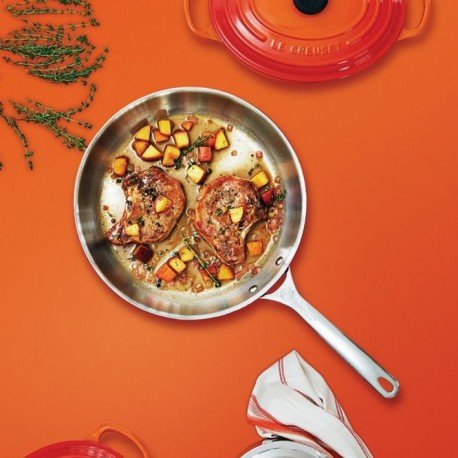

Example: When a pan is heated and used to cook a food what happens is that energy is transferred from the pan to the food by means of conduction.

Source: http://tienda.canalcocina.es/sartenes-woks-y-paelleras/638-sarten-3ply

Convection

It is the mode of energy transfer that occurs between a solid surface and a fluid or an adjacent gas that is in motion and includes the combined effects of the conduction and the movement of fluids, it should be noted that in the absence of fluid movement it would only be a pure driving mechanism, also the greater the movement of fluids it is known that the heat transfer ratio will be higher.

Example: The cooling of the soup fresh from the kitchen is often done by the environment, as when our mothers tell us "your food will be cold if you do not come to eat", this happens because the energy contained within the Soup is first transferred to the air layer adjacent to it, by conduction. Then by combined effects of conduction and convection inside the air the energy goes away from the surface, this by the movements of the air molecules and the macroscopic movement of the air that removes the hot air from the surface.

Source: http://elektro-sol.eu/servicio/calefaccion-por-conveccion/

Natural and Forced Convection

There are technically two classifications of convection, the natural one in which the movement of the fluid is caused by the density difference in the fluid, since it changes when a temperature change occurs and the forced one, where the fluid is driven by a external medium, such as a pump or a fan.

Radiation

It is the energy emitted by matter in the form of electromagnetic waves (or photons) as a result of changes in the electronic configurations of atoms or molecules, the basic difference with the other two mechanisms is that it does not need an intervening means to perform the transfer, it is more can be done in a vacuum, this is how the Sun's energy reaches the Earth. It should be noted that there are many types of thermal radiation but the one that concerns us in this issue is the thermal radiation since it is emitted due to the temperature of a body.

Source: https://sites.google.com/site/pnoliuhyt/tercer-parcial

Based on these basic concepts, we can infer that heat transfer plays a key role in the diverse production processes we perform as human beings to maintain the current standard of living, and this is basically due to the influence of extended surfaces (used to dissipate the heat in computer processors, cabling coverage, among others), insulators (used in pot handles, coating pipes and houses, etc.) and especially by the heat exchangers that are used to control the temperature of a fluid in the industry.

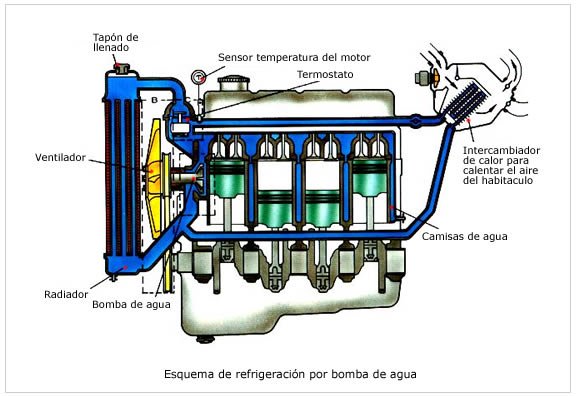

Heat exchangers

They are equipment that facilitate the exchange of energy in the form of heat between two fluids that are at different temperatures and at the same time prevent them from mixing with each other. For practical purposes they are used in a number of applications from domestic heating and conditioning to chemical processes. It differs from a mixing chamber in that it prevents the fluids from combining. It should be noted that two mechanisms of heat transfer occur in this, the convection in each fluid and the conduction through the walls that separate them, it is common to find these equipment thermally isolated from the environment in order to avoid the transfer of heat by radiation and convection, that is, not suffer losses.

Source: http://www.aficionadosalamecanica.com/refrigeracion-motor.htm

Types of heat exchangers

There are different types of heat exchanger classifications but the most important are: depending on the contact of the fluids involved, according to the configuration used or according to the service offered in the production process.

According to the contact of the fluids

-Direct contact

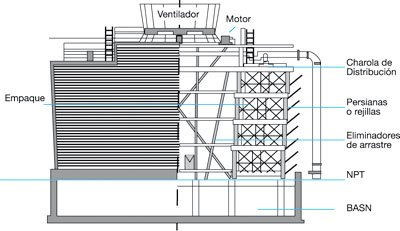

In these happens the mixture of the fluids involved in the process to regulate the temperature in this way, it resembles opening the hot water and mixing it with cold water when we bathe, although in these we study the mass transfer that occurs between both fluids for the effects of suitable approaches, as an example we have the cooling towers, commonly used to cool hot water from a cooling system in order to be recirculated.

Source: https://www.mundohvacr.com.mx/mundo/2009/03/torres-de-enfriamiento/

-Contact Indirect

These are designed so that no type of contact between the fluids occurs, this in order to be able to use refrigerant fluids or special heaters without the loss of these, recovery of heat between raw material and product (as is the case of the towers). distillation of an oil refinery or chemical processes with exothermic reactions), ensure the quality and profitability of the product in question. They can be of alternative flow, where the fluids run in the same space alternately or on a surface, where the heat transfer occurs through a surface independently of its shape and without allowing direct space. There are many examples of this that are discussed below.

According to the configuration of the equipment

- Double tube exchanger

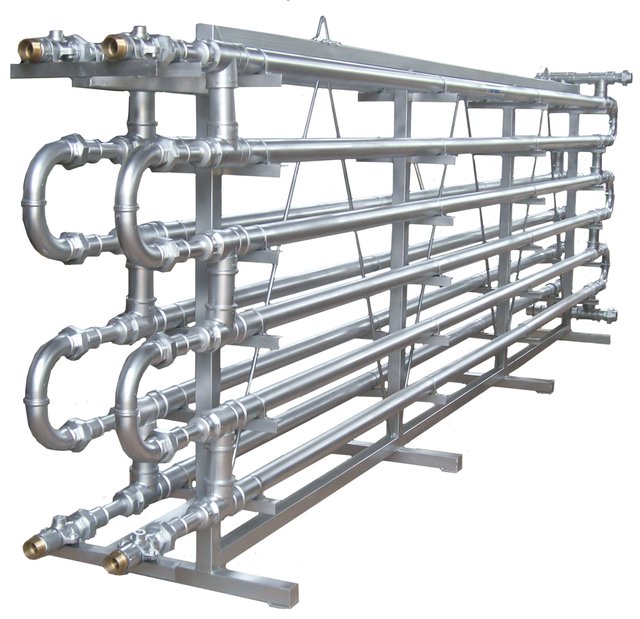

It is the simplest of the heat exchangers, in this one of the fluids goes through the smaller tube, while the other one does it through the annular space between the two tubes, the tube arrangement can be in parallel or countercurrent, according to whether the direction of the fluids is the same or opposite.

- Plate exchanger

This type of exchanger is more innovative, this consists of a series of plates with corrugated and crushed steps for flow. The hot and cold fluids flow in alternating passages, in this way each cold fluid stream is surrounded by two hot fluid streams, which results in an efficient heat transfer.

Source: https://i.ytimg.com/vi/Rw_j55PDnO8/maxresdefault.jp

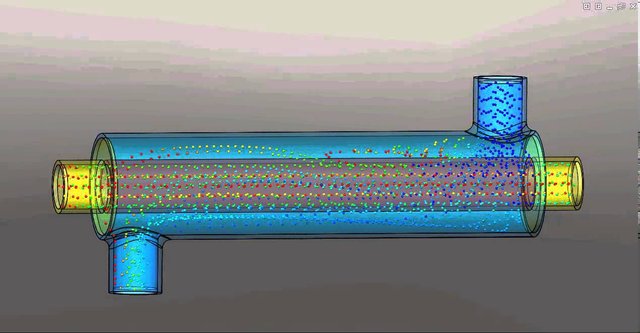

- Tube and shell exchanger

It is the most common type of exchanger for industrial applications. These contain a large number of tubes packed in a shell with their axes parallel to it. The transfer of heat takes place as one of the fluids moves inside the tubes, while the other moves outside of them, passing the shell. It is important to note that thanks to some deviators in the shell, the fluid passing through it is forced to move transverse to the fluid contained in the tubes in order to improve heat transfer.

Source: http://www.nauticexpo.es/prod/alfa-laval-mid-europe/product-30729-416225.html

According to the Service

-Refiguring

This uses a refrigerant to cool a fluid to a temperature lower than that obtained if water were used. The coolants most used in the industry are ammonia, sulfur dioxide, propane, ethane and metallic chloride, but due to their toxic effects and the extremely low temperatures that are required, R-134a, R-22, R-404A refrigerants are used , R-507 and R-410.

-Condensador

Units of tube and shell with a special physical proportion that are used for the condensation of waste vapors, that is to say that these are of direct contact. It is commonly used in thermal power plants as the heat sink in the thermodynamic cycle, that is condensing vapors from steam turbines. It also has uses in the purges of heaters that, once cooled, are incorporated into the cooling circuit.

- Cooler

Equipment in which a process stream exchanges heat with water or air without phase change (that the fluid does not solidify or evaporate) in order to dissipate heat from a current. It is used in industrial refrigeration, chemical and food processing plants, computer centers, air and water conditioning processes at industrial and domestic levels. In this row are the cooling towers.

-Recovery of heat

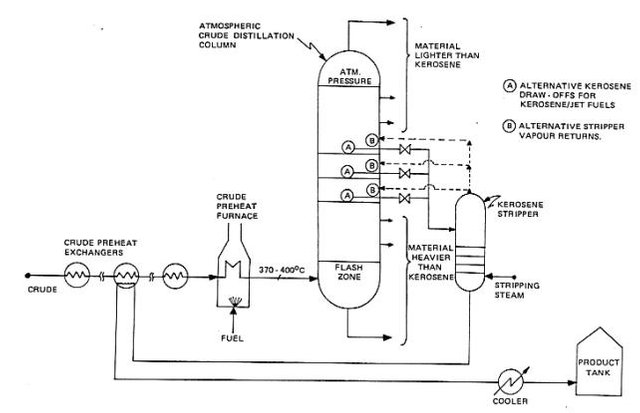

The function of these equipments is to recover the heat coming from a product and supply it to the raw material, as it happens in the reaction of sulfonation and atmospheric distillation of petroleum, in this last process, petroleum products (separated from a temperature profile in the distillation tower) exchange heat with the crude oil in order to reduce the gas consumption in the heating ovens. These help to save energy and therefore to increase economic feasibility.

Source: http://www.monografias.com/trabajos4/kerosene/kerosene.shtml

-Heater

These are responsible for increasing the temperature in a current without the need for a phase change. These are commonly used to increase the enthalpy of fluids found in tanks, so fluid movement is not necessary.

-Reboiler

It is a vaporizer that provides latent heat of vaporization (the heat that a fluid generates when it is in the state of saturation, in the process of changing from liquid to vapor). They are heat exchangers that connected to the base of a distillation column provide the necessary heat to return the steam to the bottom of the column and thus allow the distillation to be carried out, since the temperature profile is maintained throughout. tower.

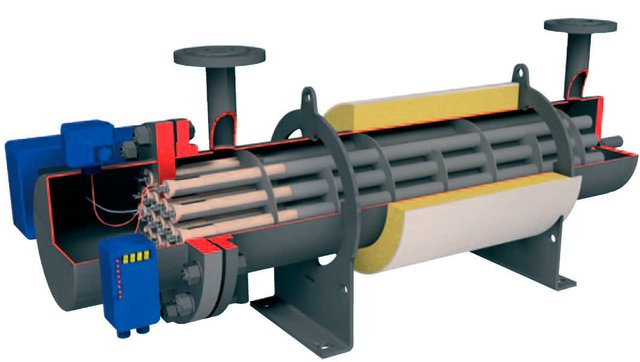

- Steam generators

They are responsible for producing heating steam in an industry, it is the most economical means of heating a fluid due to the efficiency it has, in this water is heated until its phase change by means of the combustion gases generated by the burning of gas or gas oil.

Source: http://www.directindustry.es/prod/attsu-termica-sl/product-37754-562700.html

- Overheating

It heats the steam to the discharge of a boiler above the saturation temperature, these are especially used in the thermoelectric industry. It should be noted that this steam is generally expanded.

-Vamp

It converts the liquids to steam, it is important to emphasize that this name is received when the liquid to be heated is different from water.

This publication was supported by the following authors and links:

KERN, D. (1999) Process Heat Transfer. USA, Mc Graw Hill Book Company.

CENGEL, Y. y GHAJAR, A. (2008) Heat Transfer. USA, Editorial Mc Graw Hill.

http://www.academia.edu/7767151/GUIA_DE_INTERCAMBIADORES_DE_CALOR_TIPOS_GENERALES_Y_APLICACIONES