Industrial equipment and machines have greatly reduced the complexity involved in performing chemical changes, it is no rocket science to learn how a machine is used, one with proper determination could learn how to operate any machine within a short period of time provided the machine is in good condition.

Therefore it is necessary not to be alarmed by the title of this tutorial, the steps are pretty basic.

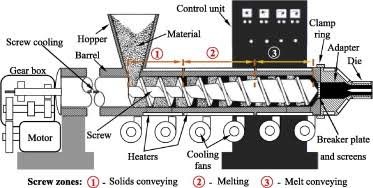

This is an overview of the Equipment used for this process, An Extruder

STEPS

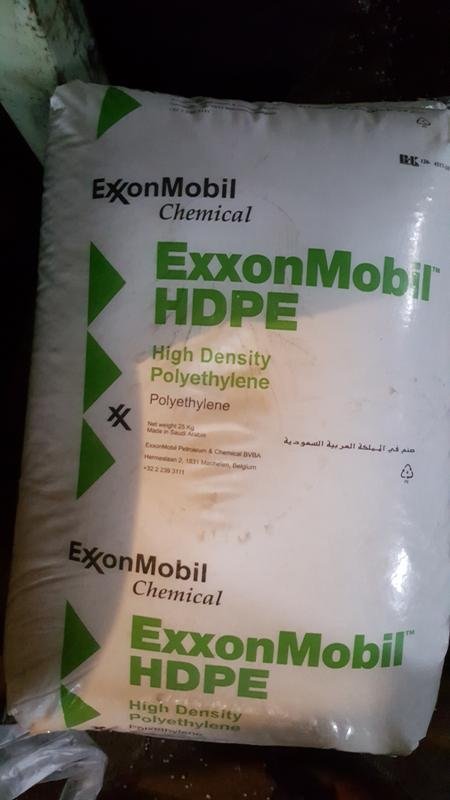

First, Obtain your feed (High Density Polyethlyene (HDPE) pellets, which comes in 25kg bags)

There are variations, each company produces its HDPE to its desired texture

You could also mix different produce to achieve your desired feed texture

Next obviously, would be switching on the machine, preparing it for heating before turning on the various components

The control box for process control and monitoring

After which would be to input the raw materials (HDPE Pellets) into the feeder

The Feeder is connected to the heating compartment where the feed undergoes conversion powered by the motor engine

These pellets are heated and drawing into filament, which are passed into the blowing component of the extruder, where Air surges through it, which expandes it to the desired width and thickness

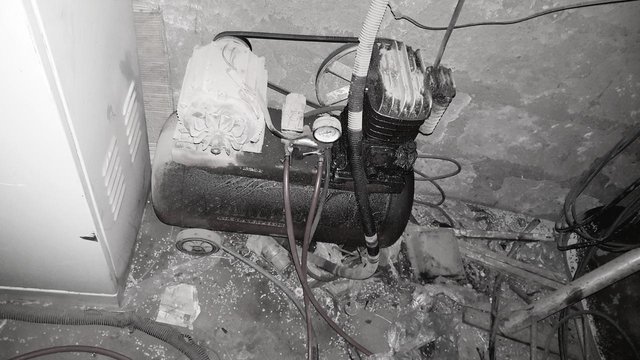

Air capacity through the blower could be increased by connecting an air compressor directly to the blowing component

Next we adjust the width and thickness, while cooling the produce by natural convention, we achieve this by passing the formed sheets through a tower and then to the compact roller

The compact roller rolls the sheet into a fold.

One roll is usually 50kg in weight which is the weight of 2 bags of HDPE (ie)

2bags/roll.

Here is a stack of rolls

This completes the first lesson, the second will feature the cutting and sealing of the sheets into finished products.

What an interesting description of the process. I must say, I had no idea. Your pictures make it very detailed.

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Thanks that was the objective

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

I just love this kind of stuff. Thanks for a really great demonstration.

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Thank you too. I believed it had to be practical

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Wait! Are those not the pellets people were sending some months back as plastic rice? (Sure they are)

For your post, its a sure guide to Do-It-Yourself methods for those who care. You taken the whole industrial process so simplified that i can actually instruct another party to accomplish the whole process over the phone! Thanks to your article.

Good work you've done here.

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Glad it was useful to you. I really appreciate

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Nice! What is the power consumption of this machine? How do you produce nylons of different colors?

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

I like your post. What I am more concerned about is the health hazards in the manufacturing facility. Is is adequate - can you describe health and safety measures in the facility? I am very interested in such processes. I am a chemical technologist and I enjoy reading about topics like yours. The photos make it even better.

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Nope the process and raw material are perfectly safe. You could even chew them but dont swallow . The only measure to be taken is the normal equipment precaution, knowing not to touch the heat compartment with bare hands or the motor etc . But not external safety measures

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

I see. Thanks for the explanation.

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit