1) WHAT IS THE CONCRETE?

Material (artificial stone) used in construction formed by mixing in adequate and precise amounts of binder, to which particles or fragments of an aggregate, water and specific additives are added.

The binder is in most cases cement (usually Portland cement) mixed with an adequate proportion of water to produce a hydration reaction. The cement and the water form a paste that surrounds the aggregates, constituting a heterogeneous material. Sometimes certain substances, called additives, are added that modify or improve some properties of the concrete. The elements that make up the concrete are divided into two groups: active and inert. The water and cement are active, and the chemical reaction through which they are forced to reach a state of great solidity (they represent around 30% of the final mixture). The inert elements (aggregates) are gravel and sand, whose fundamental role is to form the "skeleton" of the concrete occupying a large part of the final volume, with which it is achieved to reduce it and to significantly reduce the effects of the chemical reaction of the setting, particularly those referring to excessive shrinkage by setting (represent about 70% of the final mix).

Source

In theory, when the concrete mix is adequate, each aggregate particle is completely surrounded by paste, and all the spaces between the aggregate particles are completely filled. It is worth mentioning that soil particles between 0.075 and 4.75 mm in size are conventionally referred to as sand, while gravel is between 4.75 and 76.20 mm, although for construction purposes it is 9.5 a 38 mm.

Both the water and the aggregates must be inert materials (clean of silt, clays and salts) or, failing that, with a maximum of 5% impurities, in order to generate optimal conditions for a good reaction. chemistry between cement and water, and generate good adhesion between cement paste and aggregates.

The quality of a concrete depends on several factors, among which are the following:

• Quality of materials.

• Correct dosing of materials.

• Execution of mixing.

• Drained and vibrated during placement.

• Curing of the placed concrete.

2) WHY IS THE CONCRETE ARMED?

The simple concrete is an ideal material to withstand the efforts of understanding, however, offers little resistance to stress efforts. It is for this last reason, so they are added longitudinal reinforcement bars in the area of stress, so that the steel takes these efforts that the concrete alone would not be able to resist. This combination of simple concrete with steel is called reinforced or reinforced concrete.

It is the most popular and developed, since it takes advantage in a very efficient way the characteristics of good resistance in compression, durability, fire resistance and moldability of the concrete, together with those of high resistance in tension and ductility of the steel, to form a composite material which brings together many of the advantages of both component materials. Properly handling the position and amount of the reinforcement, a remarkably ductile behavior can be achieved in elements subjected to bending. On the contrary, the behavior is very little ductile when the failure is governed by other limit states such as shear, torsion, adhesion and compression axial load. In the latter case the totally fragile character of the fault can be eliminated if transverse reinforcement is used in the form of a band.

Source

Concrete is subject to major deformations due to shrinkage and plastic flow, which causes its rigidity properties to vary over time. These phenomena must be considered in the design, adequately modifying the results of the elastic analyzes and precautions should be taken in the structuring and dimensioning to avoid excessive arrows or cracks due to volumetric changes. Because of its moldability, concrete lends itself to taking the most suitable forms for the required structural performance and, due to the freedom with which the reinforcement can be placed in different quantities and positions, it is possible to achieve that each portion of the structure has the strength necessary for the internal forces that arise.

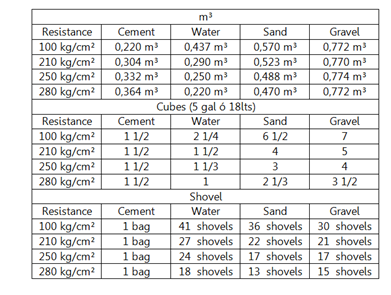

3) DOSING OF THE CONCRETE FOR 1M3 OF EACH RESISTANCE.

To dose a mixture of concrete is to determine the most practical and economic combination of the available aggregates, in order to produce a mixture with the required degree of manageability, which when hardening at the appropriate speed acquires the characteristics of strength and durability necessary for the type of construction in which it will be used.

Dosages for 1 m3 of each resistance:

Thank you for reading.

For more information, visit the following links:

Undoubtedly the concrete changed the way we build our homes and modern buildings

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit