**INTRODUCTION (continued)**

PRODUCTION OF CONCRETE

Concrete production is the process of mixing together the various ingredients—water, aggregate, cement, and any additives—to produce concrete. Concrete production is time sensitive.Once the ingredients are mixed, workers must put the concrete in place before it hardens.

In modern usage, most concrete production takes place in a large type of industrial facility called a concrete plant , or often a batch plant. It involves the following steps:

Concrete plant Facility in Mansfield Ohio

Concrete plant Facility in Mansfield Ohio

Batching

Before mixing is carried out, the ingredients have to be measured in their correct proportion to enhance the quality of the concrete.

Concrete mixing plant in Birmingham,Alabama in 1936

Concrete mixing plant in Birmingham,Alabama in 1936

Mixing

The purpose of mixing is to coat the surfaces of Aggregate particles with cement paste and to make it a uniform mass.

Decorative plate made of Nano concrete with High-Energy Mixing (HEM)

The quality of mixture depends on the accuracy of proportioning of the materials and the method of mixing.

Thorough mixing is essential for the production of uniform, high-quality concrete.

Transportation

This involves the means of conveying concrete from the point of mixing to the point of placement. The choice of transportation depends on the size and complexity of the site, weather condition and the height of the placement of the concrete.

Placing

Before the concrete is placed in the formwork, the inside of the formwork is thoroughly cleaned and a release agent (lubricant) is applied after the formwork is blown off dust.

Compacting

The Compacting of freshly placed concrete is to make it a unit mass by eliminating voids within it. The method and the type of compaction given to concrete depend on the nature of work.

Pouring and smoothing out concrete at Palisades Park in Washington DC.

Pouring and smoothing out concrete at Palisades Park in Washington DC.

Curing

After the placing and compacting of the concrete it is allowed to sufficiently harden for a day then the curing process comes in which involves the prevention of the evaporation of moisture in the concrete. This is done to avoid shrinkage of the concrete and cause a more permanent and durable material produced.

USES OF CONCRETE

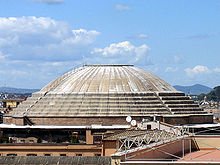

Concrete’s versatility, durability, sustainability, and economy have made it the world’s most widely used construction material all over the world. It can be engineered to satisfy a wide range of performance specifications.

It is used in highways, streets, parking lots, parking garages, bridges, high-rise buildings, dams, homes, floors, sidewalks, driveways, and numerous other applications.

ORDINARY PORTLAND CEMENT MORTAR

It is commonly known as cement mortar, it is created by mixing powdered Ordinary Portland Cement, fine aggregate and water. It was invented in 1794 by Joseph Asp din and patented on 18 December 1824, largely as a result of efforts to develop stronger mortars.

Roman mortar on display at

Chetham's School of Music.

It was made popular during the late 19th century, and had by 1930 become more popular than lime mortar as construction material. The advantages of Portland cement is that it sets hard and quickly, allowing a faster pace of construction.

Furthermore, fewer skilled workers are required in building a structure with Portland cement.

As a general rule, however, Portland cement should not be used for the repair or repointing of older buildings built in lime mortar, which requires the flexibility, softness and breathability of lime if they are to function correctly.

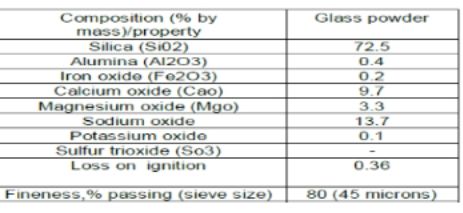

WASTE GLASS AGGREGATE

Glass is a non-crystalline amorphous solid that is often transparent and has widespread practical, technological, and decorative usage. It is a 100% recyclable material it can be recycled without any loss of quality.

Chemical composition of waste glass powder

Now a day’s many recycling companies realize that they have a loss in processing glass because recycling process involves collecting, sorting, transporting, beneficiating and manufacturing glass back into new glass products and has cost embedded in each step of the process.

In 2011, 506000 tonnes of glass was sent for recycling and bought in 200000 tonnes. 27300 tonnes of glass couldn’t be recycled and sent for disposal. Glass industry produces approximately 0.7% of waste broken glass, which comes under Non-hazardous waste. This can be recycled and utilized under building application.

Every metric ton of waste glass recycled into new product saves 315 kilograms of carbon dioxide from being released into atmosphere during creation of new glass. If glass waste is disposed into landfills it can possibly take million or more years to breakdown.

In order to avoid environmental problem that would be created if they were sent to landfills, this need to be recycled and reused. Glass is 100% recyclable material, it can be recycled without any loss of quality for example use of waste glass as cullet in glass production, as an aggregate substitute in concrete, used in reflective paints for highways, to produce fiber glass, as raw material for production of abrasives, in sand blasting, etc.

Recycling of waste glass by converting it into aggregates saves landfill areas and also reduces the demand for extraction of natural raw material for construction activity. This thing really helps to conserve the conventional natural aggregate for other important works.

REFERENCES

Production of concrete

Ordinary Portland cement mortar

http://www.cement.org/library/catalog

Well done engineer

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Thanks to you

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

What are the cost implications?

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

This is the cost implications summary in Nigerian naira

Of which the equivalent in sbd is approximately 90sbd at present exchange of 1sbd to #950

Any support will be much appreciated sir.

Thanks

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Hello @dtwo, do not copy and paste other works and try to pass it off as yours, it is called plagiarism and not allowed on steemstem.

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Thank you very much

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Hello @dtwo please check these links 1, 2 to learn how to make quality steemSTEM content.

Just as @stemng stated, do not copy-paste other people's content.

You can also join steemstem community on discord to learn more.

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Thanks to you

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Congratulations @dtwo! You have completed some achievement on Steemit and have been rewarded with new badge(s) :

Click on any badge to view your own Board of Honor on SteemitBoard.

For more information about SteemitBoard, click here

If you no longer want to receive notifications, reply to this comment with the word

STOPDownvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit