Hello everyone and I hope our day have been stress-free. I really want to enlighten us about the laser printing technology, it is a very fascinating one and I promise to not bore you.

There are two major printers that are commercially available and these are laser printers (HP popularly tagged their laser printer series as Laserjet) and Inkjet. Laser printers generally make use of dry inks in the form of toners and makes faster impressions on papers than inkjet printers. But why would laser of all available lighting technologies by applied in printing?

[different types of desktop printers. Credit: Flickr. CC BY 2.0 license. Author: David Mellis.]

Lasers are used not just because lasers has high precision but also because of the interesting relationship between light and electrons. From atomic perspective, electrons orbits the nucleus and these orbits are energy levels. These levels can be viewed as “stairs” whereby the higher energy an electron has, the higher up this “stair” the electron exists. But as this electron moves higher or acquires energy, it becomes less stable within this “stair”.

Electrons can be made to climb higher up this stair by exposing them to light. The same thing happens when the electrons lose their energy and steps down from its initial energy level, they give off their energy also in the form of light. The amount of energy given off determines the wavelength of the light it will give off and subsequently, the color of the said light.

How recent is laser printing technology?

It is worth stating that the first laser was developed in 1960 and its name was Ruby Laser named after the aluminum oxide crystal which was a major component of the lasing system. The ruby laser always give off red colored light because of the replacement of aluminum atoms in the ruby with chromium atoms which can absorb both blue and green lights to produce specifically red light. Though laser printers was not developed immediately lasers were invented, it is relatively recent technology.

The first copier was developed in 1947 as a result of the collaboration with Chester Carlson, who actually invented it, with an institution in New York City, Battelle Memorial institute. The copier was developed under a company named Xerox (initially called Haloid Corporation) and for this, they named the copier technology after its name; Xerography.

Xerox developed many copiers and soon, other companies joined the business and adopted the name Electrophotography instead of xerography Xerox named it and it became a commercial name for the copier technology and is mostly abbreviated EP for electrophotography. One thing is significant about the electrophotography of that age, it only in prints black and white (monochrome) even if the source was multicolored.

Though Canon made a significant progress in the color printing technology in 1973, it was not successful. Not until 1975 when Xerox developed the a better commercial color printer than the one developed by Canon with a trade name of Telecopier 200 and was purely based on the laser technology and formed the basis of laser printing technology which is in use today.

Electric field and charge

A good understanding of laser printing technology demands a prio knowledge of electrostatics and charges. Electrophotography which is the underlying technology of laser printers largely depends on the ability of certain materials to be able to transition from being either a conductor or an insulator depending on the intensity of light falling on them (photosensitive materials).

))

[ Credit: Wikimedia CC3.0 license. Author: Brighterorange]

The concept of electrostatics is very easy to experience in reality. Apart from the popular "hair, pen and paper" experiment which most of us carried out during our basic school days, we can also experience electrostatic forces when we blow out the balloons and rub it against our cloths. The balloon will stick to our cloths after rubbing it against our cloths and this is due to electrostatic charges which builds up during the rubbing process.

Measuring the quantity of electrostatic charge that built up in these materials can be very difficult, hence a better way to measure these charges would be to measure, for example in the pen and paper example, the speed with which the paper "runs" to the pen and also the mass or weight of the paper which will give us quantities we could apply some formulas to arrive at the electrostatic force.

The peculiar thing about charges is that when the same charge comes in contact, there's a form "disagreement" between these forces and this is seen as a repelling effect exerted on the bodies that were brought together. Hence, in the pen and paper example, either the pen or the paper is negatively or positively charged.

Another concept worth explaining is the electric field. Consider a very simple experiment where the two ends of a well charged battery is connected to two separated flat electrodes. If these electrodes are left in a dusty environment for a period of time, a close examination of the electrodes will show that the distribution of the dust particles are not uniform. Since many dust particles are likely to be positively charged, there will be more collection of dust particles on the negative electrode due to the electric field setup between the two electrodes which are not even connected but the air around the electrode are poor conductors but can be experienced from the dust distribution.

The printing system

The major difference between the laser printer and the photocopier is in their image source, whereas the image source for a photocopier is from a physical paper whereby a very bright light falls off to make an impression on a photosensitive drum, the image source of a laser printer is of the digital form. Hence, whereas the photocopying machine is "given image" as source, the printer has to "create" the source internally and the process of creating this image will form a big part of this work.

Generally, the laser printing system consists broadly of the printer itself, the computer and software. The computer takes care of most of the software needs of the laser printer and is also controls a part of the microcontroller which controls the sensors local to the printer. The software requirements of the printer includes the operating system which host various printing application programs (like browsers, word processors, image editors etc.), printer drivers. The digital copy which is converted to hard copy by the laser printers originated from application programs.

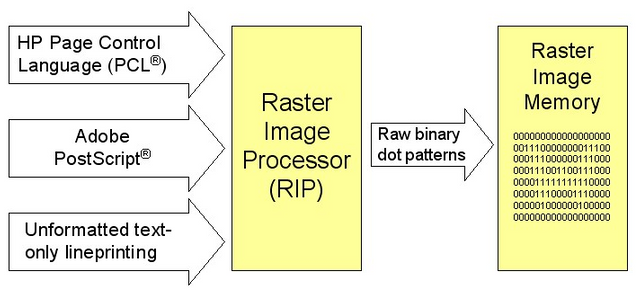

[Operation of the Raster Image Processor. Credit: Wikimedia. Creative Commons Attribution-ShareAlike 3.0 and Creative Commons Attribution-ShareAlike license versions 2.5, 2.0, and 1.0.]

Once a user issues a print command using the application program, the digital copy is sent to the printer in a format known as the description language. A specialized processor called the RIP (Raster Image Processor) receives this digital copy formatted in a description language and further formats the incoming digital signal into electrical signal which will be interpreted as several dots to make readable impressions on paper.

This operation is straightforward for monochrome prints but for colored prints, this specialized processor creates as many page as there are colors present in the digital source. For instance, if a page contains, say five colors, the processor makes five page images corresponding to the five colors and these pages are printed simultaneously on the same paper making color prints take longer time than black and white prints.

))

[Papers are made to move within the printer in "C" or "S" path. Credit: Pxhere. CC0 creative license. Author: unknown]

As already stated, the laser printer also contains one or more microcontrollers which controls the speeds of various movable parts of the printer. The printer also contains electrical system capable of setting up enough electrostatic charges required for the electrophotography process.

Within the printing system, papers are made to travel through a path which is shaped in the form of “C” or “S” and this is mainly to allow the printing process run its full course without needing to make the printer itself look bulky or shapeless.

The sensors controlled by the microcontrollers within the printer tells the printer if it is out of paper or if a paper jam has occurred. Most paper jam are cause by electrostatic build up within the paper chamber causing the papers to stick to each other making the paper picking process inefficient.

How electrophotography works

The process of writing using light is a very complex process in reality and maybe you could consider treating that paper you just printed with more carefulness. The electrophotographic process described in here was not done bearing any product in mind and was done to describe general operation of electrophotography, hence, there would be many variations in reality.

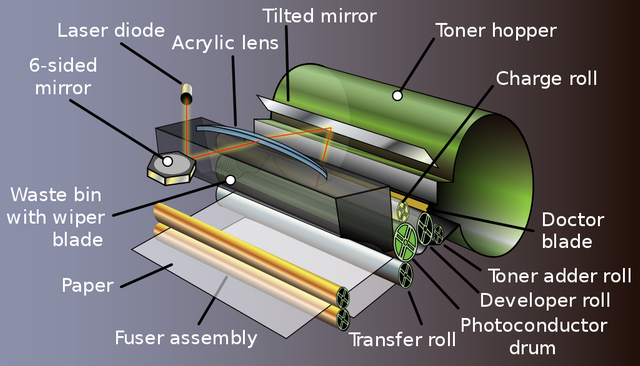

To summarize the process even before I begin to foster understanding, the electrophotographic process involves printer components like the laser scanner which throws the electrical signal from RIP to a photoreceptor. The photoreceptor works together with the charge roller, cleaner (works as the name implies), the developer, the transfer roller (which helps in the mobility of the paper) and the fuser. Now lets get more in detail.

Preparing the photoreceptor

In the previous section, I stated how important the ability of a material to change its conducting ability with respect to the intensity of light it is exposed to, is essential in the general operation laser printers. A component capable of doing this is called the photoreceptor or more specifically, Optical photo conductor (OPC). Commercially, it is known as the print drum.

[Components of laser printers. Credit: Wikimedia. Creative Commons Attribution-Share Alike 4.0 International license. Author: KDS4444.]

The photoreceptor consists of metal surface in the form of a drum coated with a very thin layer (about 0.025 mm) of organic chemical. This drum connected to an electrically charged surface and rotates in the same direction as the printing paper. The drum is made to be as uniform as possible and hole-free (even a hole as tiny as a needle end is dangerous) as the strong electrostatic charge present in the surface of the drum can damage the whole system or in a more serious manner, fire outbreak.

Apart from being extremely uniform in the surface, the drum also ensures sustains the electrostatic charge on its surface and also as the name implies, be an insulator in the absence of light and a conductor in the presence of light, hence, semiconductors are mostly used in constructing the printing drum. Since a frequent use of the printer also means the coating of the drum will wear out with time, the drum is also user replaceable.

Electrostatic Charging of the photoreceptors

As stated earlier, the photoreceptor sits on an electrically charged surface, this charged surface is made possible by the charge rollers. Initially, this electrostatic charges are created using a very expensive component called Scorotron. The scorotron is still in use today but only in special printers which requires faster and larger prints because of its cost.

Most commercial printers makes use of the charge rollers to create this charged surface for photoreceptors. The charge roller has a metallic central rod, with a rubber coating on the outside since it makes direct contact with the photoreceptor. To create static charges, an electric potential is set across the central rod while the center of the photoreceptor is kept at zero potential, this creates strong electrostatic charge between the charge roller and the photoreceptor as both start moving at the same speed while rubbing against each other’s surface.

To ensure that the charges created are uniformly distributed in the surface of the photoreceptors, the rubber coating of the charge rollers are carefully selected. To make the surface conductive, particles of carbon are carefully distributed throughout the surface of the rubber. The ability of the surface of the charge roller to uniformly distribute charges on the optical receptor is very crucial as unequal distribution on the surface of the drum can create holes on the organic coating of the drum which would lead to poor printout and possibility of rendering the whole system unusable.

Creating the digital image

Once a uniform charge has been achieved on the photoreceptor by the charge roller, the optical receptor is ripe to receive impression from the laser scanner. The laser scanner is situated just above the photoreceptor. The laser scanner consists of a polygon disk which is well polished on all sides making the surface a very good reflector. Within the same scanner is a very tiny semiconductor diode (a diode actually) and series of optical setup like lenses and mirrors which helps light emitted from the laser diode to reach the photoreceptor surface.

))

[Credit: Wikimedia. Creative Commons Attribution-Share Alike 3.0 Unported, 2.5 Generic, 2.0 Generic and 1.0 Generic license. Author: Yzmo]

To make an impression on the photoreceptor, the laser diode turned on and off depending on the signal it receives from the RIP. The light from the laser diode is carefully guided using lenses and mirror until it creates impressions called a Spot on the optical drum. The polygon disk is rotated in such a way that the image it will reflect from the optical diode at extreme angle will correspond to the either end of the optical drum (photoreceptor). A movement from one end of the drum by the light reflected from the polygon disk (mirror) to the other end of the drum is called a scan line.

As stated earlier, the RIP converts the digital image from the computer in the form of descriptive language into electrical signals and these electrical signals are in the form of dots which are arranged in the form of scan lines. When we look closely at the print cartridges of inkject printer, we would see the ink(s) moving to and from in a line while the paper is rolled across each swipe of the ink cartridge, this swipe is the scan line and the same is applicable in laser printers. Images and texts displayed by the computer are arranged in lines and these lines corresponds to the scan lines.

The impressions made on the photoreceptors are in the form of lines which consists of series of dots. These are not visible to human eyes as they are patterns made on “perfectly” distributed electrostatic charges. The part of the photoreceptor that was exposed to the laser (“On” signal) becomes less illuminated than the part that was not exposed to the laser light (“Off” signal). This pattern of charge created on the photoreceptor by the laser light is called a Latent image and if it can be viewed by the human eye would look like the sent image to the printer in a reverse orientation. The part of the drum that did not receive a spot from the laser becomes the part of the paper without an ink or impression.

Creating real image

Once the image is developed on the photoreceptor, it is ready for real impression on the paper and this is where the toner comes into play. The toner is actually a plastic resin which is in the form of a very fine powder with the ability to melt at the right temperature. The most popular resin used in making modern toners is the polyester. The ability of static charge to build up and maintained by a toner power (tribocharging) and its thermal properties are major properties considered when determining the type of resin that would be used as toners.

[Credit: Maxpixel. CC0 creative commons license. Author: unknown]

In the tribocharging ability of resin, some resin has the ability to receive and retain positive charge while some can only be charged negatively. The electrostatic charge that is built up and maintained between the toner and the photoreceptor determines the quality of the print and some external factors like humidity can greatly influence electrostatic charge build up.

Pigments are used to color the toner for multi-color printing while carbon is widely used for plane black toners. Another material used for coloring black toners is iron oxide which naturally has the ability to stick to surfaces. The concept of surface area plays important role in the uniformity of the charge on the toner particles. While larger surface area (larger particles) tend to receive lesser electrostatic charge, smaller particles gets charged quite faster and are generally more charged, hence, when the toner has been literally ground, sizing is required to separate particles of different sizes.

In fact, the process of making toners whose particles are of the same size (approximately) and can be charged uniformly is a very tasking process which makes the toner a very costly part of the printer.

REFERENCES

- Laser printers -wikipedia

- working principle of laser printers -explainthatstuff

- How Laser Printers Work -howstuffworks

- History of laser printers -history-computer

If you write STEM (Science, Technology, Engineering, and Mathematics) related posts, consider joining #steemSTEM on steemit chat or discord here. If you are from Nigeria, you may want to include the #stemng tag in your post. You can visit this blog by @stemng for more details. You can also check this blog post by @steemstem here and this guidelines here for help on how to be a member of @steemstem. Please also check this blog post from @steemstem on proper use of images devoid of copyright issues here.

))

))

You did a very expository piece bro.

I remember when I was in the university, I used to refill toner in cartridges for people, as a way of getting additional income 😃.

You just brought back old memories bro

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Lol, you've really hustled hard and I'm sure it's paying off. I am really fascinated by the overall operations of the laser printer. Thanks buddy.

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Hi @henrychidiebere!

Your post was upvoted by utopian.io in cooperation with steemstem - supporting knowledge, innovation and technological advancement on the Steem Blockchain.

Contribute to Open Source with utopian.io

Learn how to contribute on our website and join the new open source economy.

Want to chat? Join the Utopian Community on Discord https://discord.gg/h52nFrV

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Electrophotgraphy!

I have always wondered how those machines do the printing precisely. No wonder they charge us higher.

Nice piece bro

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

That got me enlightened, believe me am knowing this for the first time, this laser printer would save alot cus catrige has given us headache

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit