Why did I go for the FlashForge Creator Pro?

Because I was interested in 3D printing, I decided to buy a 3D printer. Because I had no idea of the topic and there were so much printers to choose from, I was initially overwhelmed and had to first get a picture.

After some googling it was clear to me that I want to have a finished printer and not a kit.

My budget should not exceed 1000 €.

After reading some tests, I chose the FlashForge Creator Pro.

Here are the reasons:

- open source

- large volume of construction

- double extruder

- good reviews

Long story short, I've ordered it.

Arrival / Unboxing:

The packaging made a solid impression.

Included were: SD Card, 2 x build tape, power cable, usb cable, some tools, 2x spool holder,2x filament guide tube, leveling card

Of course, I had no idea where to place the printer. So I put it on the ground. The supplied filament rolls were quickly mounted and the print bed aligned thanks to the leveling code on the SD card and the leveling card.

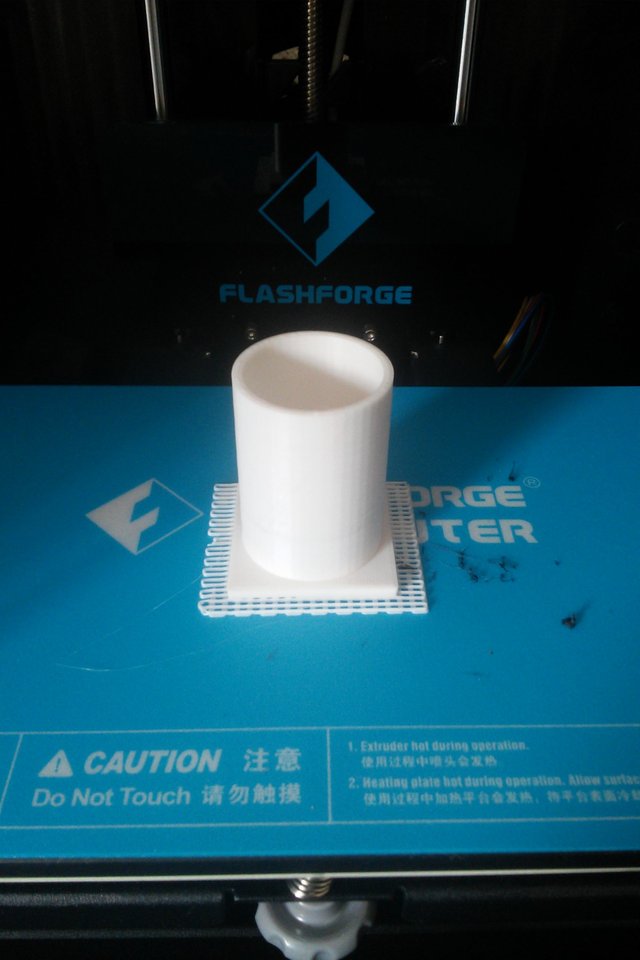

On the included SD card were also some test prints available. So I started the first print without further ado.

The result was good, it was a cylinder on a base plate. In the middle were raised Chinese scripts.

Trouble with the software:

Since Flashforge is Open Source, there are several programs that you can print with.

On the SD card I came across the program "ReplicatorG". This is a free 3D printing program which has not received any updates since 2012.....

The program freezes constantly and has crashed my laptop several times. In short, it is not recommended.

Unfortunately, I found out relatively late that Flashforge provides a free program (Flashprint).

For beginners, this program is recommended. With Flashprint I made my first self-designed prints.

I use SolidWorks to construct my projects.

There are some settings in the software that are not easy to regulate in the beginning. (for me)

Problems that occurred:

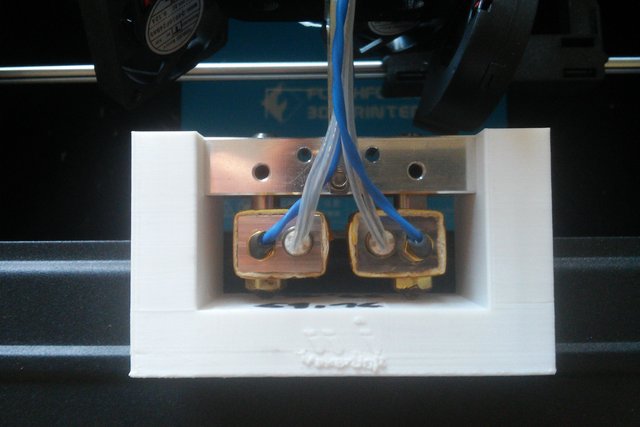

After a few prints, the first problems arose that no material came through the extruder anymore.

The extruder had to be removed.

Since it is a closed printer, all work had to be done in the printer. Since it is a printer with double extruder, both extruders had to be brought up to the same height. I used a gauge that I found at "Thingiverse".

This proved difficult because there was little space and the printer was standing on the floor.

After the extruder was reinstalled, the problem recurred after a short time. I was desperate because I spent more time working on the printer than on the actual printing.

Last but not least, I found that the supplied filament was of poor quality, which indicated that the diameter of the filament was fluctuating.

I ordered new filament, which caused the next problem. Because the new filament rolls did not fit on the original holder. First of all, I had to design and print universal mounts.

In addition, I decided to put the printer on a table to get a better height to work on it and balance the printer.

I placed a strong wooden panel and a rubber mat under the printer to minimize the vibration.

At this point I would like to go back to the filaments. I have had my experiences with the following three filaments.

ABS, PLA and PETG.

ABS: Was rather difficult to print as it often did not adhere properly to the print surface.

Also the whole apartment stank of plastic

PLA: It was a pleasure to print. The print results were usually very good.

The adhesion on the print bed was always excellent.

PETG: Printed just as well as PLA, it is very stable and resistant which is why I like to print it.

I hope that you liked my article, I would like to thank all who have read this so far.

I know that much of my article was only scratched or completely missing, everything else had blown up the frame.

If something is unclear or you have questions please post it in the comment section.

Many Thanks!

I upvoted your post.

Best regards,

@Council

Posted using https://Steeming.com condenser site.

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit