First time operating one of the 5 components of a drilling system, now we have majorly 5 components which include circulating, rotating, hoisting...

Its a dream come true for any petroleum engineering student to stand on a rig floor, but to operate it is something else, now that was how I spent today.

We been planning this for some time now, starting from 1st year till date, we always had an excuse at the last moment, probably no contribution from some side or class captain unable to purchase the fuel required to run the prime movers, well not today.

This is/was going to be our last time doing a course that requires drillling practice and what better way to end it than power on the drilling rig, yea you read it right power on the drilling rig.

First the requirements was diesel as the school already provided all other requirements, the class was to contribute a little to top up the existing fuel.

From definition given seems when a diesel engine cut, aka use up all fuel within is storage tank, certain amount of air starts getting sucked in, which in turn develops difficult in bringing it on, you would have to bleed the air off before starting it, not your regular petrol powered engines I must say.

The machines used today are

- Air compressor

- Prime mover.

An air compressor is a device that converts power (using an electric motor, diesel or gasoline engine, etc.) into potential energy stored in pressurized air (i.e., compressed air). Source.

The air compressor used here was suppose to operate on a 12v battery but due to difficulty to kick start it, it was connected in parallel with another 12v battery, to always provide electricity supply, not the wisest of choice, probably in an ideal situation such wouldn't be allowed, but we not going to power it all day, just few hours to operate the air hoist.

Next was the prime mover, two prime movers can be seen/ used.

One operates to power the mud pump and the other to power the draw works.

You probably understand, that the rig been used here is a mechanical/rotary rig, mechanical cause it operates/transfer powers via chains and sprocket.

Our major concern today is operate the hoisting system.

To kick start this practical we ensured both machines were operational, checking the oil levels, bleed those that requires it and ensured the fuel was good enough/sufficient to work within the desired time.

Few minutes later, the machine was on and running and man did it produce a loud noise, became almost impossible to hear what your fellow colleague could say, probably the proximity to the machine was too close.

Next we had to climb up to the rig floor were the practical would take place today.

The rig is for demonstration purpose, although all facilities are working properly and gives you a clear picture of what to expect from a standard rig, but then in a smaller picture.

For safety reasons, mobile phones were not allowed and due to poor planning we were unable to get a digital camera to capture this great moment.

Both machines were running, although I earlier said we had two prime movers to power the draw work and the mud pump, will be working on the hoisting system so no need to get the mud pump up and running.

Mud pump is incharge of circulatory system, which involves sending mud down the hole, to lubricate the bits, clean the wellbore and bring back cuttings which are analyze. This probably going to be done if we lucky or by attending a short course but I doubt you would handle the equipment.

Our concern today is the hoisting system.

Function

Lower Raise and Suspend

Lower aka trip in, raise aka trip out and also to suspend.

I could go on and on about the little I know about the hoisting system lol but lets get a summary version of it.

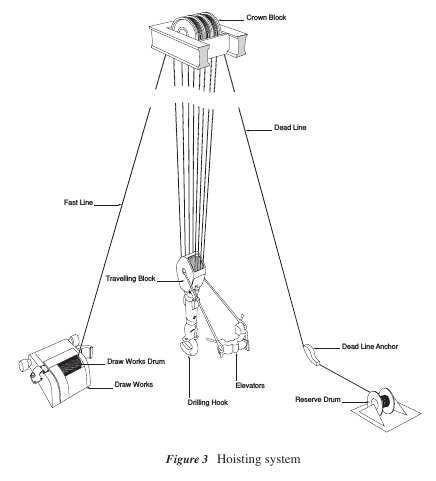

The hoisting system is a large pulley system which is used to lower and raise equipment into and out of the well. In particular, the hoisting system is used to raise and lower the drillstring and casing into and out of the well Source.

With that been said, we are going to operate the drawworks, to raise the connected kellypipe and also the kelly bushy to see the master bushy, what it looks like and the turn table as well.

The draworks, just like a big drum connected with strands of wire which is attached to the travelling block, connected to the travelling hook which is used is raising, lowering and suspending.

It is connected to a drillers console were activities which involves operating the drawwork and also rotating the master bushy which in turn rotates the kellypipe and every other sub surface connection.

From the drillers console board, you can clearly see the controls and their name written on it.

When we trip out, we do so at a slow pace, this can be archived by moving both the drawwork brake and slow control simultaneously, which in turn raise/trip out.

To trip in/lower, we need to raise the drawwork brake alone, leaving the slow control constant, this in turn trip in the pipe.

For a mechanical rig, a single joint is connected at a time, the pipe is brought from the pipe rack and dropped in the mouse hole which is later connected when needed.

After getting and also handling the brake it was time to teach us how to drill.

When drilling, you first of all rotate before trip in/lower.

So the rotation control was on and the kelly bushy was seen to rotate, which in turn, the kelly pipe started rotating as well, the drawwork brake was moved up again and the kelly pipe started moving into the well bore, now we were rotating and same time tripping in.

Drilling was archieved here, although when drilling you have to first circulate mud, before lowering your drilling bit but for demonstration purpose and the fact, we were operating the hoisting system made us did the above.

Next was bringing the pipe from the pipe rack to the rig floor, the equipment used here was the air hoist, it did not require the prime mover for operation so it was turned off.

The requirement here was the air compressor, which was left on.

The procedure to bring the pipe up was not difficult a bit, and after getting the point it was time to shut down the air compressor and our objective for today had been archieved.

We gradually climbed down the rig and took our leave.

The practice took 1hr30mins and would have loved it if we carried a digital camera alongside us.

It is critical to cite/reference sources for articles/blogs of this nature.

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Thanks for the above, although the words been used above was actually my own understanding of the live drilling practice that took place, and the definition I got online to give a little summary of what I was driving out was sourced.

Thanks for the above and would try to do a better work of citation next time

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Congratulations! Your post has been selected as a daily Steemit truffle! It is listed on rank 21 of all contributions awarded today. You can find the TOP DAILY TRUFFLE PICKS HERE.

I upvoted your contribution because to my mind your post is at least 7 SBD worth and should receive 64 votes. It's now up to the lovely Steemit community to make this come true.

I am

TrufflePig, an Artificial Intelligence Bot that helps minnows and content curators using Machine Learning. If you are curious how I select content, you can find an explanation here!Have a nice day and sincerely yours,

TrufflePigDownvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Awesome post! You should try to use the #geology in the future!

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Thanks for the suggestion, much appreciated

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit