In this paper, the development of Li - ion battery is reviewed from several aspects, such as material technology, monomer battery and battery system.

- lithium manganate is generally used in light electric vehicles, and can also be mixed with ternary materials to improve the safety and multiplying power performance of batteries for new energy vehicles;

- lithium iron phosphate is suitable for power batteries with medium specific energy requirements;

- the ternary material is suitable for high specific energy batteries after improving safety through material, membrane coating and battery technology;

- graphite cathode is still widely used as cathode material, and efforts to add high capacity materials such as silicon to carbon cathode material are still in progress, and liquid electrolyte is developing towards high voltage and wide working temperature range;

- the small cylindrical battery, the square metal shell battery and the soft-pack battery have their own characteristics, which are suitable for diversified application requirements of electric vehicles;

- the technical level of domestic manufacturing equipment continues to improve, and battery system technology requires a cooperative effort on the whole vehicle and battery to improve safety and reliability.

Lithium - ion battery is the most practical power battery at present. it is expected that its specific energy can be increased to 300 ( w h ) / kg in the near future to meet the development needs of new energy automobile industry in the next 10 years.

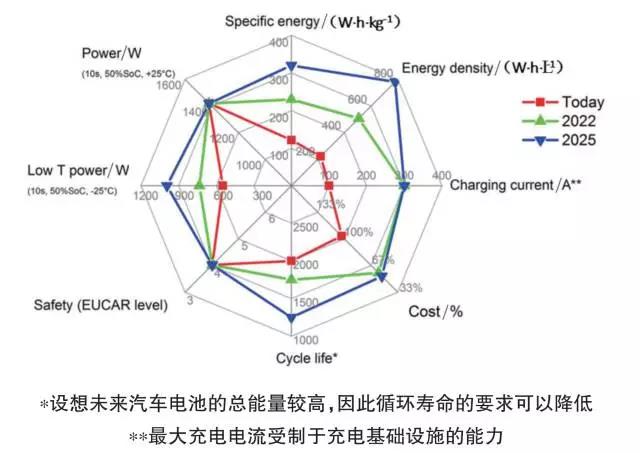

The development of electric vehicles needs better batteries. the specific energy, life, safety and price of power storage batteries are very important for the development of pure electric vehicles. Figure 1 shows the current technical level of commercial power batteries and the expected attainable target for the next 10 years [ 1 ], often these indicators are contradictory, relevant performance needs to be taken into account in the actual product design. The development of materials and battery manufacturing technology provides support for the rapid development of the electric automobile industry. lithium ion battery has the advantages of high specific energy, low self - discharge, long service life and so on. it is the most practical value of electric automobile battery at present, and has been widely used in hybrid vehicles, pure electric vehicles and fuel cell vehicles.

lithium ion battery material technology

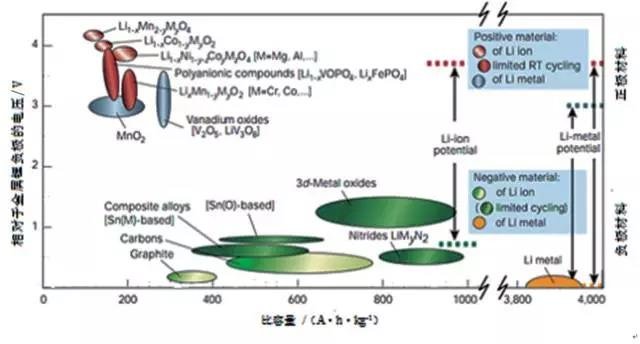

The lithium ion battery uses a lithium embeddable material as a negative electrode, a lithium-containing compound as a positive electrode, a polypropylene / polyethylene porous membrane as an isolation layer, a lithium salt is dissolved in an organic solvent as an electrolyte, and four key materials of the lithium ion battery are composed of a positive electrode material, a negative electrode material, a separator and an electrolyte ( fig. 2 ). Lithium - ion battery anode and cathode material system is very rich [ 2 ], high potential reversible release of lithium ion lithium compounds and low potential reversible storage of lithium ion materials can constitute its anode and cathode materials.

With the development of doping and surface modification technology and the progress of electrolyte technology, the charging voltage of lithium cobaltate / graphite system is increased to 4.40v, the specific capacity of the material can be increased to 200 - 210 ( ma h ) / g [ 3 ], and the real density of the material and the compaction density of the pole piece are the highest in the existing anode materials

Spinel structure of lithium manganate ( LiMn2O4 ) has three-dimensional lithium ion diffusion channels, low raw material cost, simple production process, high thermal stability, good overcharge resistance, high discharge voltage platform, high safety. The disadvantage is that the theoretical capacity is relatively low, the dissolution of manganese element may affect the life of the battery in high temperature environment and other problems, can be coated on the surface of Al2O3 LiMn ( 2 - x ) alxo4 solid solution to improve the high temperature cycle performance and storage performance of LiMn2O4 [ 4 ], suitable as a low-cost battery for light electric vehicles. Domestic lithium manganate material because of the industry competition price drop significantly, mainly to meet the needs of the mobile power supply, electric tools and electric bicycle market, there is a trend of low-end development, high temperature cycle performance needs to be further improved.

Ncm ternary layered anode materials are mainly used in power batteries, in addition to nickel, cobalt, manganese accounted for 1 / 3 of lini1 / 3co1 / 3mn1 / 3o2 in power batteries more mature application [ 5 ], higher capacity lini0.5co0.2mn0.3o2 has also entered the batch application. Ncm ternary materials are commonly used in electric vehicle batteries with lithium manganate. the specific energy of the single battery with ncm as the main positive electrode active material can be increased to 180 ~ 200 ( w h ) / kg. the development of higher capacity nickel-rich ternary materials is also underway

Lithium iron phosphate battery safety is high, long service life [ 7 ], China is currently the world 's main lithium iron phosphate materials and battery production. At present, the stability of the nano-power type material and the high-density manganese-iron-lithium phosphate energy type material are developed rapidly, and the requirements of the domestic market and the popularization of the new energy automobile in China at the present stage are gradually met, especially the application of passenger cars and special vehicles, and the nano-power type material is also applied to the fields of electric energy storage and communication backup power supply. The properties of high energy and high power materials tend to be stable and the cost is further reduced. high voltage spinel lithium manganate and high voltage high specific capacity lithium manganese-based anode materials are still being developed.

Negative electrode material

The cathode materials that can be used for power batteries include graphite, hard / soft carbon, and alloy cathode materials.

Graphite material is widely used in lithium ion battery cathode material, reversible capacity of 360 ( ma h ) / g, has reached the limit, the intermediate carbon microspheres charge rate performance is better than natural graphite, but the cost is high, amorphous hard carbon or soft carbon can meet the needs of the battery in higher rate and lower temperature applications, began to apply, but mainly mixed with graphite applications.

The lithium titanate cathode material has the optimal multiplying power performance and cycle performance, and is especially suitable for high-current charging applications. in recent years, the problem of battery inflation has been basically solved through surface modification and electrolyte matching technology, and the lithium titanate cathode material can be applied to batteries requiring rapid charging, and has the disadvantages of low specific energy and high cost of the produced batteries.

Nano silicon has been proposed in the 1990s for high capacity cathode [ 8 ], by adding a small amount of nano silicon material to improve the carbon anode material capacity is still a hot research and development, reversible capacity of 450 ( ma h ) / g of nano silicon or silicon oxide negative material has begun to enter a small batch application stage, but due to lithium embedded silicon volume expansion caused by its actual use in the battery cycle

Electrolyte

Lithium ion battery electrolyte generally uses high dielectric constant cyclic carbonate and low dielectric constant linear carbonate as organic solvent [ 9 ], and lithium hexafluorophosphate as solute. With the continuous improvement and renewal of electrode materials, the requirements for matching electrolyte are also higher and higher.

Generally speaking, the electrolyte of lithium ion battery should meet the characteristics of high ionic conductivity ( 10 ( - 3 ) - 10 ( - 2 ) s / cm ), low electronic conductivity, wide electrochemical window ( 0 ~ 5v ), wide working temperature range, good thermal stability ( - 40 ~ 60 ℃ ). In addition, there are many kinds of additives, mainly divided into conductive additives, film additives, booster additives, flame retardant additives, etc. Lithium hexafluorophosphate and other novel lithium salts, solvent purification, electrolyte preparation, functional additives technology continues to progress, the current development direction is to further improve the working voltage and improve the high and low temperature performance of the battery, the safe ionic liquid electrolyte and solid electrolyte are being developed.

Diaphragm

Polyolefin microporous membrane with its excellent mechanical properties, good electrochemical stability and relatively cheap characteristics, is the main variety of lithium ion battery membrane market [ 10 ], including polyethylene ( PE ) monolayer film, polypropylene ( PP ) monolayer film and PP / PE / PP three-layer composite microporous membrane.

Domestic manufacturers using dry process production, wet process PE membrane also has a number of enterprises can be mass production. The technology of membrane ceramic coating has been popularized. high temperature and high voltage resistant membrane is the future development direction. - cell technology

So far, the basic design of lithium ion battery is still the same as Sony 's patent application published in 1989:

The lithium compound anode active material, carbon black and other materials are mixed with an adhesive to be pulped, coated on a current collector aluminum foil, dried and rolled to form a cathode sheet;

Carbon anode materials such as graphite are coated on the copper foil, and the anode sheet is manufactured by the same method as the anode;

A thin membrane such as microporous polypropylene is inserted between the positive and negative electrode sheets as an isolation layer, wound or laminated into a cylindrical shape or a rectangular shape, loaded into a battery shell, and the positive and negative electrodes of the battery are led out by welding;

Then adding electrolyte solution, forming and sealing to obtain the monomer battery.

The shape of the monomer is cylindrical, square metal shell ( aluminum / steel ) and square soft package bulk:

Cylindrical batteries used to be mainly used in notebook computers, now Tesla and other companies choose 18650 cylindrical batteries and larger diameter and length of the cylindrical battery, the battery is made by winding.

Square battery capacity is larger, the battery is produced by winding Rao, z - shaped lamination, winding + lamination, positive electrode coating lamination, lamination + winding, etc.

The flexible battery cell is manufactured in the same manner as the square metal shell cell.

Its advantages are as follows:

Cylindrical battery technology is the most mature, low manufacturing cost, but the heat dissipation capacity of large cylindrical battery is poor, so generally choose small cylindrical battery. Vehicle battery pack capacity is large, the number of batteries, management system is more complex and expensive.

The manufacture process of wound structure battery in square battery is relatively simple, but it is mainly suitable for soft electrode plate batteries. both lithium iron phosphate and ternary material batteries can use this method, but the spinel positive electrode material batteries should be hard and cannot be manufactured in this way.

The laminated battery is suitable for various material systems, has high reliability and longer service life than the same type of wound-rao battery, and the batteries of the universal volt plug-in hybrid electric vehicle and the daily-produced leaf pure electric vehicle are manufactured by adopting the laminated process. The stack process is more complex, but has a longer life than the flat wound cells of the same material system.

By 2015, the specific energy of the lithium iron phosphate monomer battery reaches 140 ( w h ) / kg, the specific energy of the ternary material mixed lithium manganate monomer battery reaches 180 ( w h ) / kg, and the specific energy of the small cylindrical battery adopting NCA internationally reaches 240 ( w h ) / kg

Automotive power battery belongs to high-end manufacturing industry, involving many industries, technical route is still changing, foreign battery production enterprises adopt efficient, fully automatic, personnel non-contact production mode, industry cooperation mode has also changed, materials, monomer batteries and module manufacturing gradually formed a more obvious division of labor.

Foreign power battery technology and equipment level in pulping technology and equipment, coating technology, assembly line, manufacturing process on-line detection technology and other single technology, in the unit automation, process automation, integration, non-contact production, in the manufacturing control and management system integration, MES manufacturing process management, etc. are in the leading position. - battery system technology

From the point of view of commercial lithium ion power battery systems, key core technologies include:

Battery pack technology: integrated battery pack, thermal management, collision safety, electrical safety, etc.;

Battery management system ( BMS ) electromagnetic compatibility technology;

Accurate signal measurement technology: such as monomer voltage, current, etc.;

Accurate estimation of battery status: such as SOS, SOC, soh, sof, etc.;

Battery balance control technology, etc.

The BMS and other key components of the battery system, including sensors, controllers, actuators and other components are basically dominated by automotive electronics powers ( Germany, Japan, the United States ).

At present, China has begun to carry out research in related fields, and achieved corresponding results. Some enterprises have successfully developed smart meters ( compact, integrated with current, voltage, insulation and electrical measurement, etc. ), can replace foreign current, voltage, insulation sensors. Battery pack technology, due to the integration of battery pack, thermal management, collision safety, electrical safety, and so on, the technology is complex, the international automobile enterprise technology is more mature. Domestic research units in BMS electromagnetic compatibility technology, signal precision measurement technology, battery state precision estimation, battery balance control technology and other aspects of more in-depth research, voltage measurement accuracy of 0.5 %, current measurement accuracy of 0.5 %, temperature measurement accuracy of 1 ℃, SOC estimation accuracy of 5 %. Most of the power battery system products developed in China are relatively simple in function, although they have the basic detection and monitoring function, but in the reliability of data collection, estimation accuracy of SOE ( residual energy ), thermal management, balance, safety management and other aspects need to be improved, the core components of the gap is bigger.

The main factors affecting the popularization and application of electric vehicles are the safety and use cost of lithium-ion power batteries. besides the further improvement of the safety, life and consistency of the battery body, the battery modular technology, battery group technology ( integrated battery distribution group, thermal management, collision safety, electrical safety, etc. ) also has obvious gap with foreign countries.

The key technologies of battery management include integrated battery electrochemical model, electrical safety design, battery state estimation, equalization management, fault diagnosis and calibration, and charge management. The research and development of key technology and system of battery thermal management should be based on the structural design of battery pack and calculation and analysis of battery heat production, study the effect of different thermal management technology of heat dissipation and temperature equalization, get the low cost, simple process, strong safety and reliability of battery thermal management heat dissipation scheme. According to the actual application scenario, air cooling, liquid cooling, heat pipe cooling, semiconductor cooling and heat absorption of phase change materials are selected. the light weight of battery structure needs to take the battery system and the related structure of the whole vehicle as the research object, considering the coupling characteristics of each other, and carry out the key technology research of integrated optimization design of structure vibration resistance, impact resistance and light weight from two aspects of structure design optimization and material selection. In order to optimize the design scheme of components, materials, structural design, connection, etc., battery safety should be based on electrical safety, mechanical safety and thermal safety to carry out the overall scheme design and research of battery system safety, for the battery system to carry out fault diagnosis and prediction, thermal safety monitoring and early warning and prevention and control of key technologies. - conclusions

In the future for a long time, lithium ion battery is still the most suitable electric vehicle battery, progress is gradual [ 13 ], lithium ion battery material system is rich, lithium manganate anode material, ternary system anode material, lithium iron phosphate anode material, composite carbon anode material, ceramic coating membrane, electrolyte salt and functional electrolyte technology support the development of battery technology progress and industrial development.

Since the tenth five - year plan, China 's power battery from scratch, lithium manganate power battery is widely used in light electric vehicles and hybrid vehicles, lithium iron phosphate battery supports the demonstration operation and application of electric vehicles in recent years, the application of ternary anode materials in the power battery technology has made positive progress, the specific energy of monomer batteries from about 100 ( w h ) / kg to 200 ( w H. Battery system technology advances in application, safety and reliability will be further improved in the next few years.

The following aspects of r & d work in the future need to adhere to and further strengthen:

In terms of materials, it is necessary to continuously improve the existing materials such as iron phosphate, lithium manganate, ternary materials, composite carbon cathode materials, lithium titanate, diaphragm ceramic coating technology, functional electrolyte, etc., and develop high-capacity layered anode materials, high-voltage lithium nickel manganese spinel anode materials and their industrialization technology; Research and development of high voltage electrolyte with high voltage anode material; Development of high temperature and high voltage resistant battery diaphragm; The negative electrode material of silicon-based alloy and its industrial technology were studied.

Power battery design and manufacturing, need to develop new pole piece and battery structure, development of high-speed slurry new technology and equipment, precision coating die and control system, high-precision coating thickness measurement system, high-speed integrated battery core manufacturing system, battery and battery automatic equipment line and manufacturing information system ( MES ), etc., developed for China