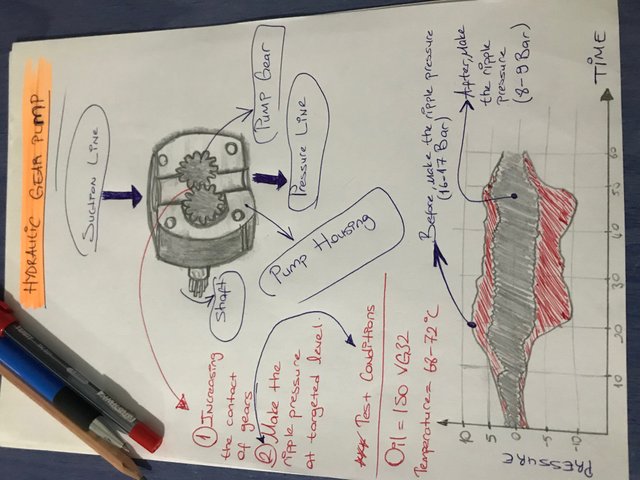

There are three different noises when the hydraulic gear pump is working; mechanical noise, airborne noise and pressure ripple noise.

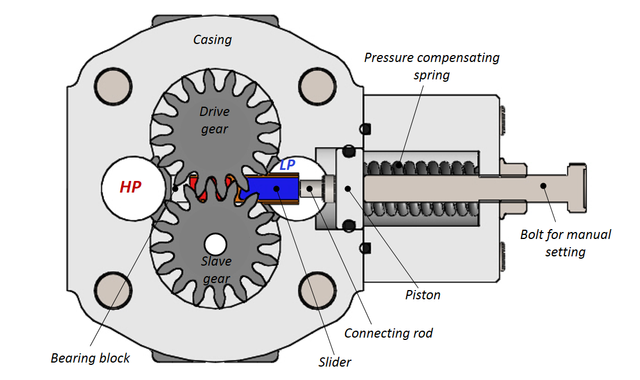

Increasing the amplitude of the pressure ripple inside the pump increases the noise level. In practice, a regulator valve is used to dampen the ripple pressure but the supportşng elements of this application are also needed.

In this study;

- Increasing the contact of gears (decrasing the backlash)

- Improving the design of lubrication channels where the gear face is working to make the ripple pressure at targeted level.

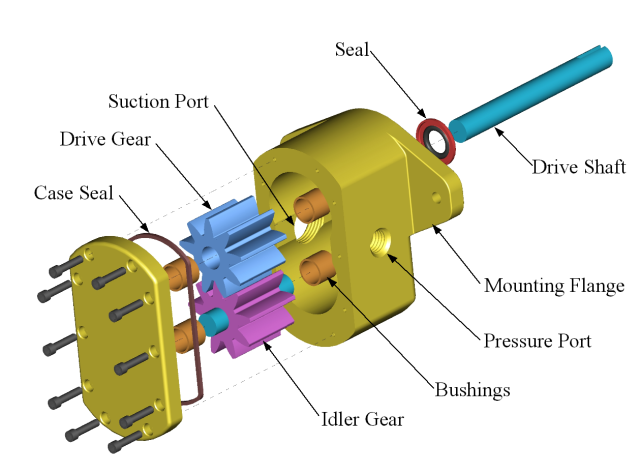

In this study, the ripple pressure of the lubrication pump which specially designed for the transmission of off-highway vehicles will be investigated and the caused noise reduction will be mentioned.