When it comes to extreme high-temperature environments, the performance and longevity of refractory materials are crucial for maintaining efficient operations. Among the many refractory options available, zirconia bricks stand out for their exceptional thermal resistance, chemical stability, and unparalleled durability. These qualities make them an essential component in industries requiring robust protection against extreme heat, chemical corrosion, and mechanical wear.

In this blog, we’ll dive into the features, advantages, and applications of zirconia bricks, explaining why they are the ideal choice for high-temperature operations.

What are Zirconia Bricks?

Zirconia bricks are specialized refractory products made primarily from zirconium dioxide (ZrO₂). Known for its outstanding thermal and chemical properties, zirconia is an advanced ceramic material with a melting point of over 2700°C. Zirconia bricks are engineered to withstand the harshest conditions in industrial furnaces, kilns, and reactors. Their high-performance capabilities make them indispensable for environments where other refractory materials would fail.

These bricks often include additives like yttria or calcium oxide for stabilization, which enhances their structural integrity under extreme conditions.

Key Features of Zirconia Bricks

Unmatched Thermal Resistance

Zirconia bricks have an incredibly high melting point, capable of withstanding temperatures exceeding 2400°C. This makes them ideal for applications in ultra-high-temperature furnaces and reactors.Excellent Chemical Stability

Zirconia bricks resist attacks from acidic and basic slags, making them highly suitable for corrosive environments. They maintain their strength and structure even when exposed to harsh chemical conditions.Low Thermal Conductivity

Unlike many refractory materials, zirconia bricks exhibit low thermal conductivity, which enhances their insulation performance and minimizes heat loss in industrial operations.High Mechanical Strength

These bricks offer exceptional resistance to wear and mechanical stress, ensuring long-term performance in demanding environments.Resistance to Thermal Shock

Zirconia bricks can withstand rapid temperature changes without cracking or degrading, making them ideal for applications where thermal shock is a concern.

Advantages of Zirconia Bricks

Enhanced Energy Efficiency

The low thermal conductivity of zirconia bricks helps to reduce heat loss, improving energy efficiency and lowering operational costs.Extended Service Life

Thanks to their durability and resistance to extreme conditions, zirconia bricks have a significantly longer lifespan than many other refractory materials. This reduces the frequency of replacements and maintenance, leading to cost savings.Versatility in Applications

Zirconia bricks are suitable for a wide range of industries and applications, from glass furnaces to metallurgical kilns. Their ability to handle diverse challenges makes them a versatile solution for many high-temperature operations.Improved Process Stability

The exceptional chemical and thermal stability of zirconia bricks ensures consistent performance, helping to maintain stable operating conditions in industrial processes.Customizable Options

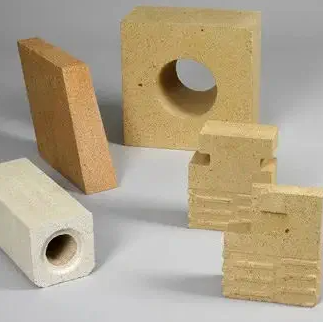

Zirconia bricks can be manufactured in various shapes, sizes, and compositions to meet the specific requirements of different industries and applications.

Applications of Zirconia Bricks

Zirconia bricks are widely used in industries where extreme temperatures, chemical corrosion, and mechanical stress are common. Some of the most prominent applications include:

Glass Furnaces

Zirconia bricks are indispensable in glass manufacturing, especially in the tank lining and crown areas of glass furnaces. Their ability to resist high temperatures and corrosive slags ensures the purity and quality of the glass produced.Metallurgical Industry

In steelmaking and non-ferrous metal production, zirconia bricks are used in furnaces, ladles, and refining vessels. Their high thermal resistance and durability make them ideal for handling molten metals.Cement Kilns

Zirconia bricks are used in the lining of rotary kilns and other high-temperature equipment in the cement industry, where they provide excellent insulation and resistance to chemical attacks.Petrochemical Industry

In petrochemical processes, zirconia bricks are used in reactors and reformers that operate under extreme temperatures and corrosive environments.Ceramic Kilns

Zirconia bricks are a preferred choice for ceramic kilns, where their thermal shock resistance and stability enhance the efficiency and quality of production.Aerospace and Defense

Due to their ability to withstand extreme temperatures and thermal shock, zirconia bricks find applications in aerospace and defense industries, particularly in testing chambers and high-temperature components.