This is inspired by @adetola because I read different posts about machining on his blog and I really like that part of mechanical engineering. His article was about manual lathe but there is a CNC lathe and this lathe and has the advantage over manual lathe because it's about more like automation where you just have program the machine to give you a particular machining and it give you what you programmed with exact dimensions given.

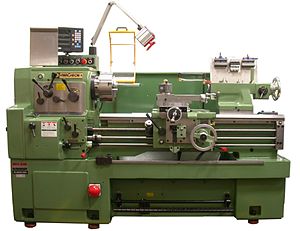

Introducing both Manual Lathe Machine and CNC Lathe Machine (Computer Numerical Control)

Center Lathe Machine

image credit: Wikipedia CC3.0 Licensed

image credit: Wikipedia CC3.0 Licensed

Manual lathe machine as the name implies is when machine operations like shaping, drilling, boring, facing etc. are done manually with the full help of an operator who will manually balance the the work piece and work tool for effectiveness and also manually apply coolant on the materials.

Typical example of a facing operation on a manual lathe machine

image credit: pixabay CC0 Licensed

image credit: pixabay CC0 Licensed

While the CNC lathe machine as the name implies Computer Numerical Control is a machine that does machine operations too like facing, drilling, shaping, turning and the likes but it is Numerical controlled I mean it runs on programs where you have to type in a program to run the operation and wait for the magic

ps: Computer Numerical Control is not just applicable to lathe machine

CNC makes machining fast and precise, having a manual lathe is not a bad idea but getting to use a CNC lathe and know what it feels like you love to consider a CNC lathe machine. At a point in ones life we just have to see what have been done before and then also follow the trend, personally before I could understand how to program a CNC lathe I understood the principles behind lathe machine and I was very conversant with the manual lathe machine.

Some of the advantages of CNC lathe are consistency, accuracy, production cost and it is possible for a operator to work with less experience.

You might be wondering why I said less experience because you are meant to have a good knowledge of how the machine works but I have my points to that. There are complex jobs you might want to carry out and it is only a skilled operator that should be able to perform such task but might not be that skilled but the CNC help you out provided you know the right Numerical codes to run the operation. I would have love to say it a small idea of artificial intelligence but it does not have a mind of his own because it works strictly on instruction and there something called dry running using softwares like G-Simple, CAMotics e.t.c where you have to do a simulation of the operation first and see the shape you intend to on a monitor before you fix in the work piece for the actual job but on the manual lathe you just have to start the job and if there is a mistake along the like you have to start all over with another workpiece of the mistake cannot be managed and that is where the precision comes in.

Computer Numerical Control lathe machine in details

CNC lathes are going to replace the manual lathe machines due to the flexibility in operations, repeatability and accuracy.

CNC machines are designed to make use of modern carbide tooling and totally use modern processes. The Numerical programming that the CNC lathe runs on are CAD/CAM processes or programming manually by the operator who has the knowledge of CAD/CAM and the uploading to the machine and finally the result of the program is produces from the occasional supervision of the operator.

The machine uses electronics via computer menu style, the program can always be edited and displayed at the on the digital display machine monitor and along with a simulated view of the process that was gotten from the dry running like I explained above.

With rapid growth in this industry, different CNC lathe manufacturers use different user interfaces which sometimes makes it difficult for operators as they have to be acquainted with them. With the advent of cheap computers, free operating systems such as Linux, and open source CNC software, the entry price of CNC machines has plummeted.source

More information about the CNC 👇

LATHE MACHINE EXPLAINED

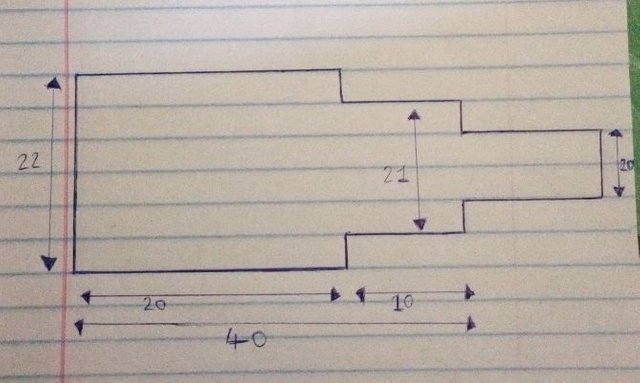

Example of making a shaft if this nature

Image source : Screenshot from my lecture note

With a CNC LATHE, this is turning operation that can take you minutes if not up to an hour on the manual lathe but with the computer numerical control lathe I just need a code below which I will write now and explain

Solution to above tasks to be carried out on a lathe

N05 M03 S1300

N10 G00 X22 Z2

N15 G01 X21

N20 Z-20 F50

N25 G00 X22 Z0

N30 G01 X20

N35 Z-10 F50

N40 G00 X22 Z2

N45 M30

The program above will produce that shaft

M03 means rotate the spindle on a clockwise direction

S1300 means at a speed of 1300rev/s

G00 means Positioning at rapid speed

X means the direction to cut and the figure in front is the dimension

Same as Z and also Y if the operation is that complex to have all the directions

N means the numbering of the program lines which can be in any form like multiple of 2 or multiple of 10 and so on

G01 means Linear interpolation

F50 means the amount of feed to take of from the material.

M30 ends the program.

More of the codes and meaning can be found 👇

Common G codes and M codes for CNC machine controls

Conclusion

The manual lathe is awesome and really interesting to work with if you are an expert just like driving a manual car and an automatic car, some people feel the automatic cars are for those that can't drive and are lazy. Same is applicable but here there is a this feeling you get when you know there is 98% perfection on a job to be done for a client.

If your are very good with manual lathe machine please give the CNC a try.

Added Information and references

Different between the manual lathe and CNC lathe machine

CNC lathe machine over manual lathe

Hi @osariemen, welcome to steemit and to @steemstem!

I invite you to read this guide for newcomers in this platform and also read here what it means to participate in the steemstem community.

You can join us on discord here

In case you do not know what discord is, please check here for instructions.

Thank you for taking the time to read my comments, please let me know if you have any questions & enjoy your time on steemit!

Katerina

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Thanks for the worm invite

I have checked the guides before this reply because when I joined the discord someone sent me the startup link and I read through since then I have not been on the discord because am more of using my laptop computer and emails because I notice I spend more time with my mobile so I am disciplining myself away from mobile

I will do my best to keep the rules obeyed

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

I just finished reading through the guide

I will keep the link handy it will be needed always.... Am grateful

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

This is an excellent post @osariemen ! Did you see CNC Milling machines taking over more of the work done by lathes or CNC/lathes ? Just one thing to clarify, where was the quote "With rapid growth in this industry..." taken from? You will need to indicate the source.

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

That depends on what the future holds

I believe the mother of all machines is the lathe for now because if your are very good with the lathe you can perform some operations meant for the milling on the lathe and there are some you just have to use the milling machine

I believe there is a possibility only time can tell

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Thanks for that correction

I just put the source

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

@osariemen, it's good to have another engineering personnel in the house. I like the area you have written about as it's one aspect of engineering that complements others. Spares sometimes are not readily available in the market and your best bet is to have it machined. You get to do that even faster and more precise with a CNC machine and thereby saving your company some loss due to production downtime.

I like the idea of you bringing us a practical aspect of CNC. You showing us a job and how it can be carried out is a good one. However, I feel you could do more to give a better illustration of how the codes works to aid the uninitiated.

In all, Kudos!

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Thanks for having me

Well you have used a manual lathe machine... Make the job easy because you understand the directions and cardinal points

What else is knowing the g-codes and practicing it... Some of the task can be really task whereby you have to take ur calculator and pens and there is also another vital part call reference point.... There is a code to determine where to take your reference point from which is G28 and G29.... You enjoy it in practical than theory

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Nice post! Do you think CNC can fit into IOT in the nearest future?

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Thanks for Commenting

I don't get your question.... Please tell me about IOT

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

I mean Internet Of Things (IoT), that's CNC can be connected to the internet.

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

CNC IS far from internet

It's garbage in garbage out..... CNC does not require internet

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Hi @osariemen! Welcome to Steemit.. :)

It is a good start though! In the Mechanical Workshop classes during our Second Semester in Engineering classes we came across this Manual Lathe Machine uses which you have explained very nicely above.

But please be careful while putting the references as @terrylovejoy mentioned in the comment and rest things you will come to know with time..

Moreover, if you find any difficulty you are always welcome in the general chat of #steemSTEM on discord to clear your doubts.

Wishing you a very happy time here! :)

Cheers!! :)

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit

Thanks for the correction and encouragement

You guys have made me welcome without being a member yet

Downvoting a post can decrease pending rewards and make it less visible. Common reasons:

Submit